Cleaning or washing is distributing water or other cleaning fluids over a product or surface to remove contaminants. Spray nozzles can significantly improve this process by providing a directed spray over the target area. This uniform spray coverage provides consistent and repeatable results, maximizing the impact and use of the cleaning media.

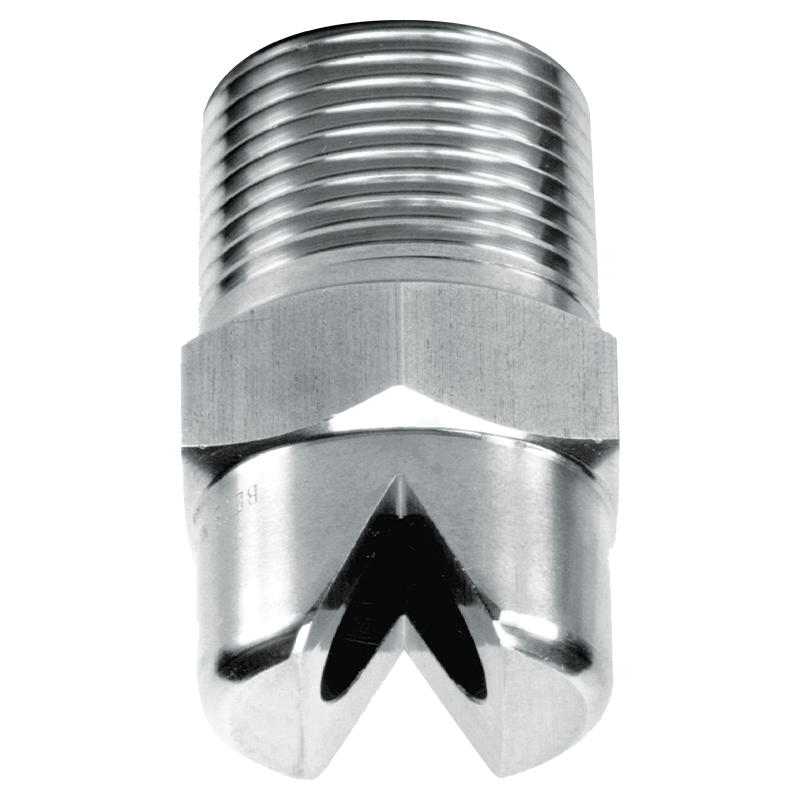

BETE offers a wide variety of spray nozzles for cleaning and washing depending on the type of soil being removed. Full cone nozzles produce medium to large droplets sufficient for washing delicate products like fruits and vegetables. Flat fan nozzles deliver high impact and superior cleaning performance for hard-to-clean residues. No matter your cleaning challenge, BETE has a spray solution for optimizing your process.

Common Uses And Industries

Important factors to consider:

Size, area, or shape

Application details and requirements

- Residue to be removed

- Temperature and chemical composition of wash fluid

- Required materials of construction for corrosive residues and spray media

- Interior vs. exterior wash

- Interior: Available bottle opening sizes

- Exterior: Available nozzle mounting locations

Available/required flow rate

- Achieve effective washing while minimizing costs of treating or disposing of wastewater

Available pressure drop (∆P) across the nozzle

- ∆P = supply pressure at nozzle inlet – process pressure outside nozzle