BETE provides a wide variety of high-performance spray nozzles and automated spray systems for coating applications. Our precision spray technology minimizes waste and overspray and ensures the even application of the spray media.

Our spray nozzles are used throughout the food industry to apply ingredients to foods, spray antimicrobials on meat and poultry, and mold inhibitors to cheeses and baked goods. Use oil sprayer systems for spraying release agents on trays and molds to prevent sticking. BETE’s Electric HydroPulse® automatic nozzles’ hygienic design for the food industry delivers uniform spray coverage with minimal waste through precise intermittent spraying.

Many industrial coating applications use spray nozzles to apply glues and resins to building materials, perfumes and lotions to tissues and fabric softeners, and flame retardants to textiles.

Our automated spray coating systems, like the FlexFlow™, ensure precision spray control and flexible automation for coating and lubricating, which improves product quality while saving resources.

Customers can trust BETE spray nozzles and sprayer systems to provide a high-quality coating for their spray applications.

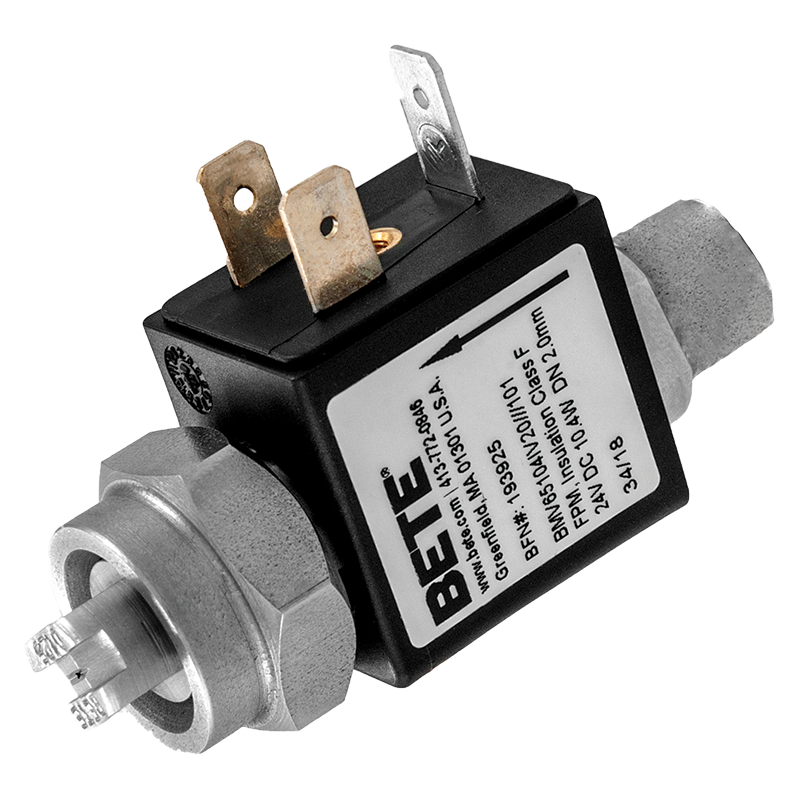

Featured Products

Find Your Coating Solution by Industry

Related Products

XA10/XA11 AUTOMATIC AIR ATOMIZING NOZZLES

Pneumatic Nozzles for Precise Intermittent Spraying

HYDROPULSE® PHP PRECISION SPRAY AUTOMATIC NOZZLES

Pneumatically Actuated Intermittent Spray Nozzles

SAM AUTOMATIC VARIABLE AIR ATOMIZING NOZZLES

External Mix Flat Fan or Full Cone Pneumatic Spray Nozzles