DESIGN FEATURES

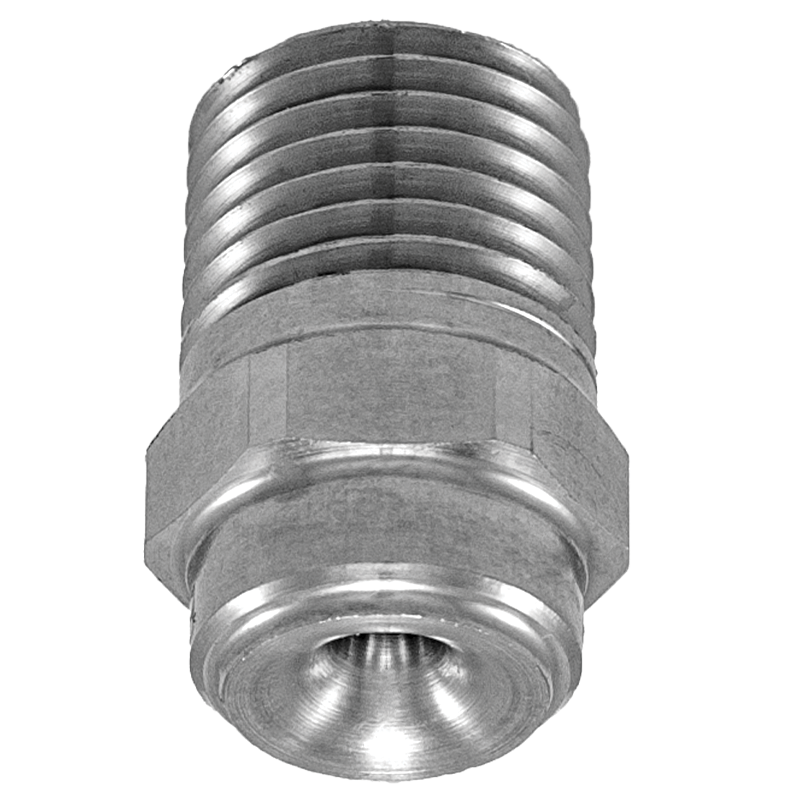

Ultimate clog-resistant design with largest free passage available in a full cone nozzle

High energy efficiency

Easily handles dirty, lumpy liquids

High-reliability spray performance under the most difficult conditions

Two unique S-shaped internal vanes, as opposed to x-vane style nozzles, allow maximum free passage of particles

U.S. Patent

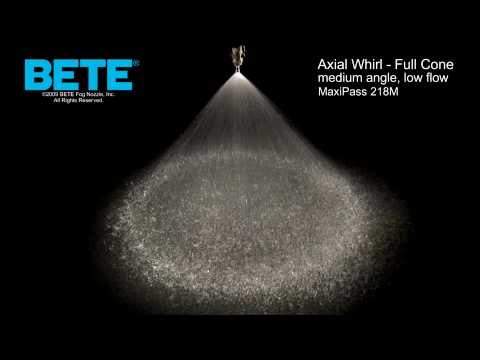

HOW SPRAY PATTERN IS ACHIEVED

Atomization is achieved by the water being spun inside the nozzle and then exiting an orifice

Produces a medium to coarse droplet size

More uniform pattern than spiral nozzles

Available Spray Angles

30 - 120°

Flow Rate Range

0.697 to 1510 gpm

Available Connection Types

- Pipe: 3/8, 1/2, 3/4, 1, 1 1/4, 1 1/2, 2, 2 1/2, 3, 4

- Connection Methods: Thread (NPT, BSP, Male, Female)

Materials

PVC, Polypropylene, CPVC, PVDF, Brass, 316, Duplex 2205, A494 CW6MC (cast Nickel Alloy 625), A494 CW2M (cast Nickel Alloy C-276), A494 CX2MW (cast Nickel Alloy C-22), A494 CU5MCuC (cast Nickel Alloy 825), PTFE, UHMW PE, Cobalt Alloy 6

Flow Rates, Spray Angles, Connections

Full Cone

Select a nozzle number below for performance graph, drawings, and to request a quote.

Flow rate (gpm/lpm) is calculated at differential pressure (psi/bar).

Nozzle Number

Connection Sizes

Spray Angles

Flow Rate (gpm) @ Differential Pressure (psi) (Density: 1 SG)

3 psi

5 psi

10 psi

20 psi

50 psi

80 psi

0.697

0.886

1.23

1.70

2.62

3.26

1.11

1.41

1.95

2.70

4.16

5.18

1.60

2.03

2.82

3.90

6.00

7.48

2.54

3.23

4.48

6.20

9.54

11.9

2.87

3.65

5.05

7.00

10.8

13.4

3.53

4.48

6.21

8.60

13.2

16.5

4.26

5.42

7.51

10.4

16.0

20.0

5.21

6.62

9.17

12.7

19.5

24.4

6.15

7.82

10.8

15.0

23.1

28.8

7.38

9.38

13.0

18.0

27.7

34.5

8.61

10.9

15.2

21.0

32.3

40.3

11.1

14.1

19.5

27.0

41.5

51.8

12.3

15.6

21.7

30.0

46.1

57.6

13.5

17.2

23.8

33.0

50.8

63.3

15.4

19.5

27.1

37.5

57.7

71.9

16.4

20.8

28.9

40.0

61.5

76.7

19.9

25.3

35.0

48.5

74.6

93.1

20.9

26.6

36.8

51.0

78.4

97.8

25.4

32.3

44.8

62.0

95.4

119

27.9

35.4

49.1

68.0

105

130

34.4

43.8

60.6

84.0

129

161

38.5

49.0

67.9

94.0

145

180

45.1

57.3

79.4

110

169

211

55.3

70.4

97.5

135

208

259

66.4

84.4

117

162

249

311

79.5

101

140

194

298

372

97.6

124

172

238

366

457

115

146

202

280

431

537

131

167

231

320

492

614

148

188

260

360

554

691

173

220

305

422

649

810

193

245

339

470

723

902

209

266

368

510

785

978