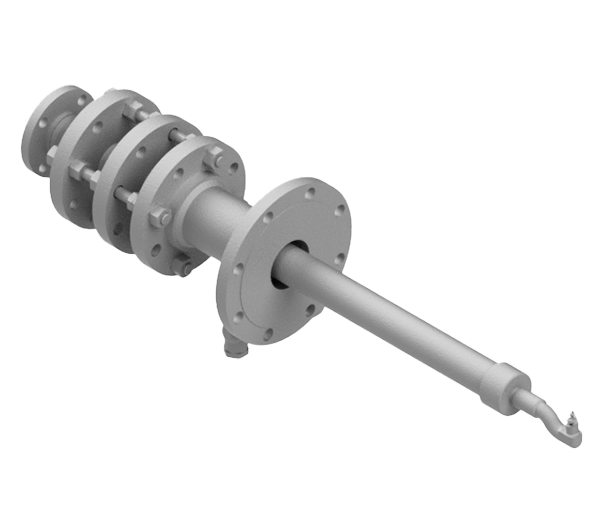

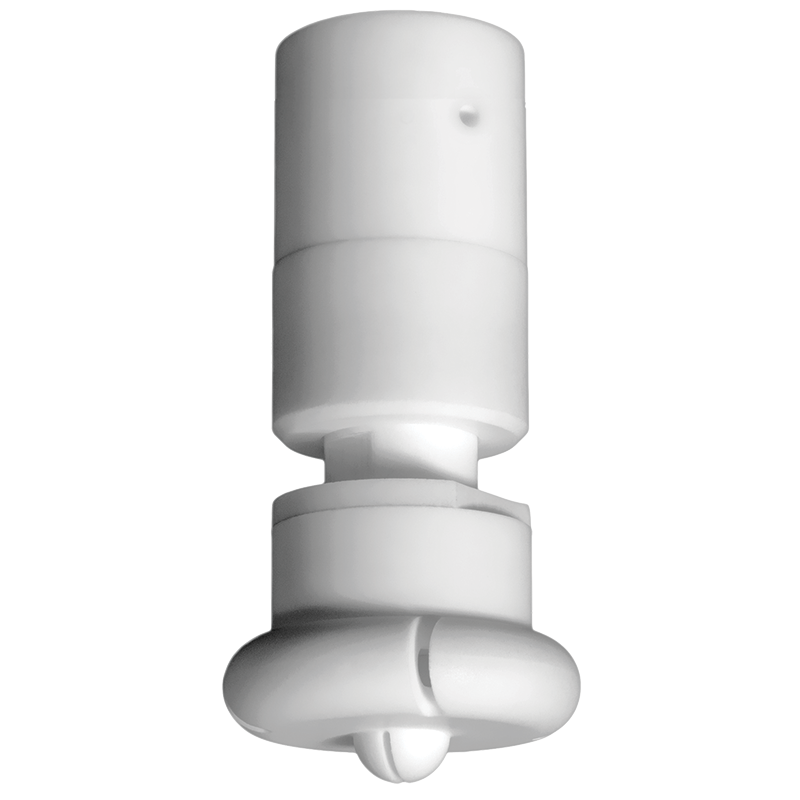

Spray Nozzles for

the Chemical Processing Industry

BETE is a trusted international spray technology manufacturer for critical chemical processing operations. We know that selecting the correct spray nozzle, lance, injector, or spray system for your chemical process is key to optimizing productivity.

Our high-quality spray technology is manufactured with durable and corrosion-resistant materials to perform in the harsh environments found in the chemical processing industry. Materials include nickel alloys and stainless steels for high-temperature environments and plastics for corrosion resistance. Cobalt alloys, silicon carbides, and tungsten carbides offer longevity for use with abrasive spray media.

Our customer-focused designers, applications engineers, and sales team work with you to find the best spraying solution for your unique application, whether it be a standard product or a custom design.

Common Applications

Contact our spray experts to find the perfect nozzle for your application.