SPRAY NOZZLES, FABRICATIONS, & SPRAY SYSTEMS

BETE manufactures tens of thousands of different products, including automatic spray nozzles, air atomizing nozzles, misting nozzles, tank washing nozzles, spray drying nozzles, spray lances, fabrications, and automated spray systems.

Use our product search guide by selecting from multiple options to find the right nozzle for optimizing your spray process.

Air Atomizing Spray Nozzles

Applications that require very fine droplets with an atomized spray.

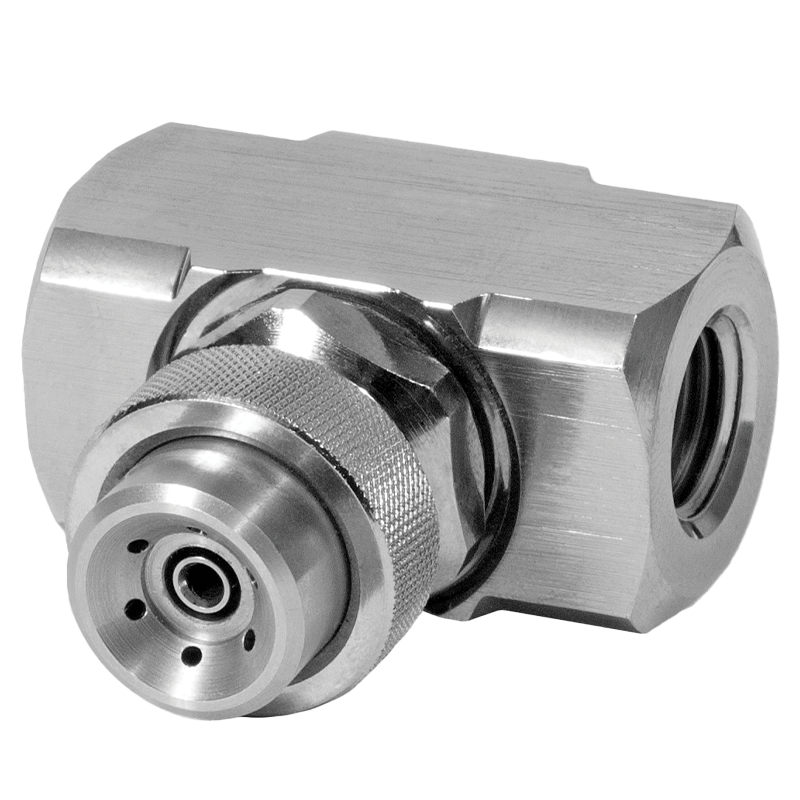

Automatic Spray Nozzles

Intermittent spray nozzles are used for precision coating, moistening, and lubrication.

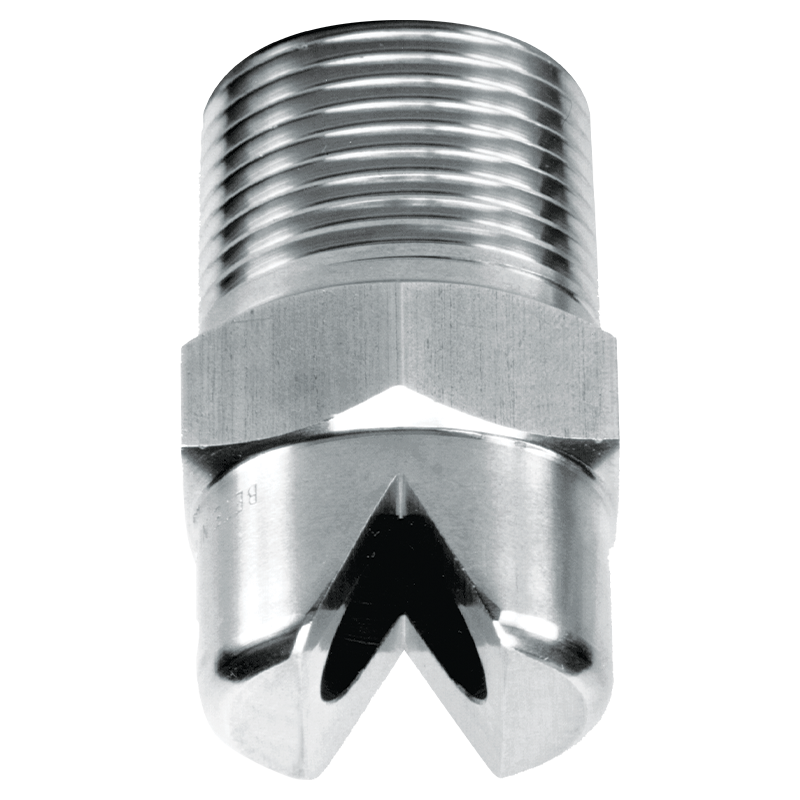

Fan Spray Nozzles

Used for impact and is ideal for conveyor applications.

Full Cone Spray Nozzles

The most frequently used type of nozzle, spray forms a conical shape with complete coverage.

Hollow Cone Spray Nozzles

Produces a thin ring of liquid around the perimeter of the cone. Ideal for cooling, gas scrubbing, and dust control.

Misting Spray Nozzles

Produces fog and misting spray for evaporative cooling, humidification, and more.

Spiral Spray Nozzles

Original pigtail design for quenching, scrubbing, and cooling.

Accessory & Special Purpose Nozzles

Nozzle accessories and specialty nozzles.

Fire Protection Nozzles

High-performance tested and certified nozzles for open-type deluge and fire protection systems.

Spray Drying Nozzles

Transforms liquids into powder form for dried foods, beverages, vitamins, and more.

Tank Mixing Nozzles

Eductors designed for mixing and agitating liquids in tanks and more.

Tank Cleaning Nozzles

Optimize your tank cleaning process with static and rotational spray.

Automated Spray System

Spray technology is designed for efficiency and automation.

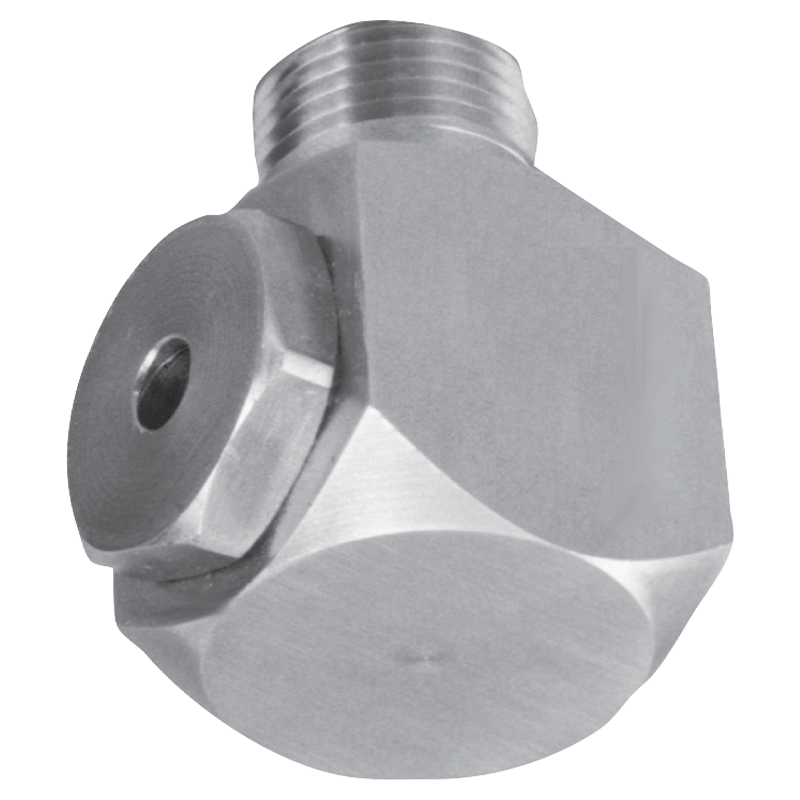

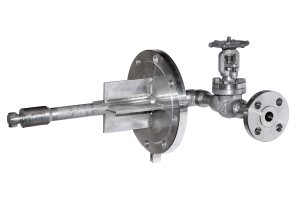

Spray Lances, Injectors, & Quills

Designed for precise nozzle placement to spray single or multiple fluids into a pipe, vessel, duct, or tower.

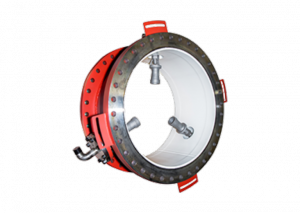

Spray Headers, Spargers, & Spools

For proper nozzle placement or nozzle arrangement.

Still Can’t Find What You’re Looking For?

Contact our nozzle experts today to help you find the perfect nozzle for your spray application.

(413) 772-0846

sales@bete.com