Fluids are atomized by combining liquid and compressed air/gas at low pressures. Atomizing nozzles produce very fine droplets ideal for coating, humidifying, gas cooling, lubricating, and misting or fogging.

Air Atomizing Nozzles

SA SpiralAir® (SA) High-Flow Air Atomizing Spray Nozzles

SAM Automatic Variable Air Atomizing Nozzles

XAXW Extra-Wide Hollow Cone Air Atomizing Spray Nozzles

Product Highlights

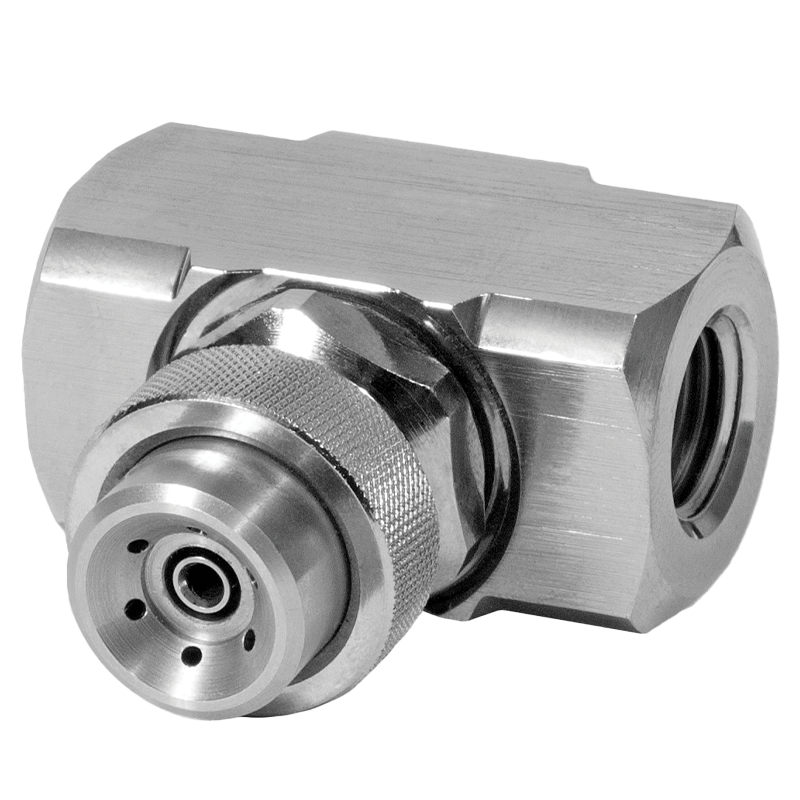

BETE XA Nozzle System - Flexible Options For Achieving Your Spray Objective

The XA nozzle system uses the energy in compressed air to produce highly atomized sprays at low flow rates. Many interchangeable components can be assembled to achieve a variety of spraying objectives.

BETE XA air atomizing nozzles produce eight distinctly different types of spray, depending on the type of air and fluid cap. The spray type and flow rate are determined by the set-up, which includes one air cap and a fluid cap.

Customers rely on BETE’s spray technology to achieve optimal spray performance with design flexibility.

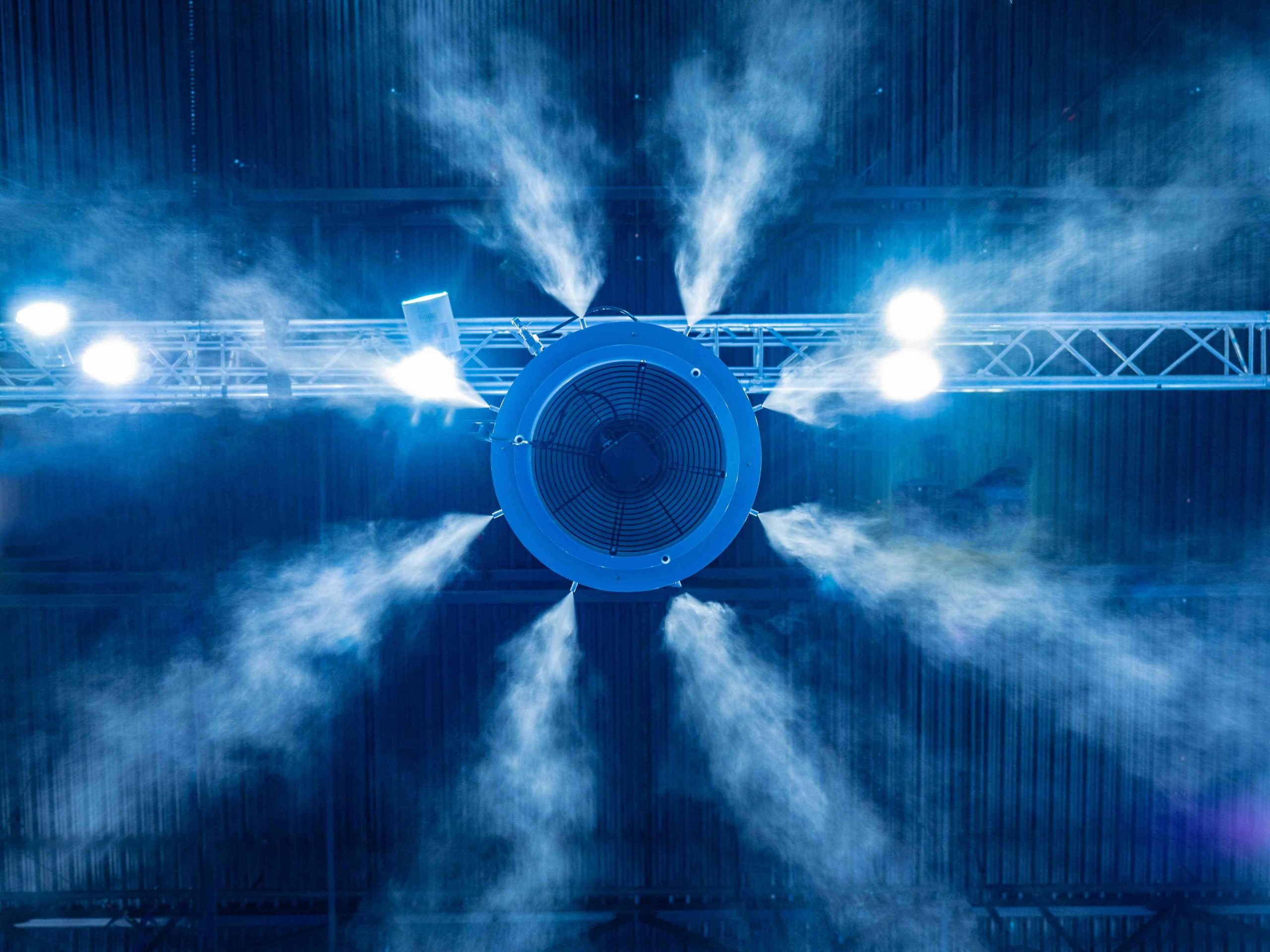

Reduce Air Consumption With BETE SpiralAir® SA Twin-Fluid Nozzles

BETE’s SpiralAir twin-fluid nozzles are efficiently designed to reduce compressed air consumption even in extreme environments. The unique three-stage atomization process delivers high performance.

Customers rely on BETE’s SpiralAir atomizing spray nozzles for improving their process, lowering costs, and saving on resources.

Air Atomizing Spray Nozzles

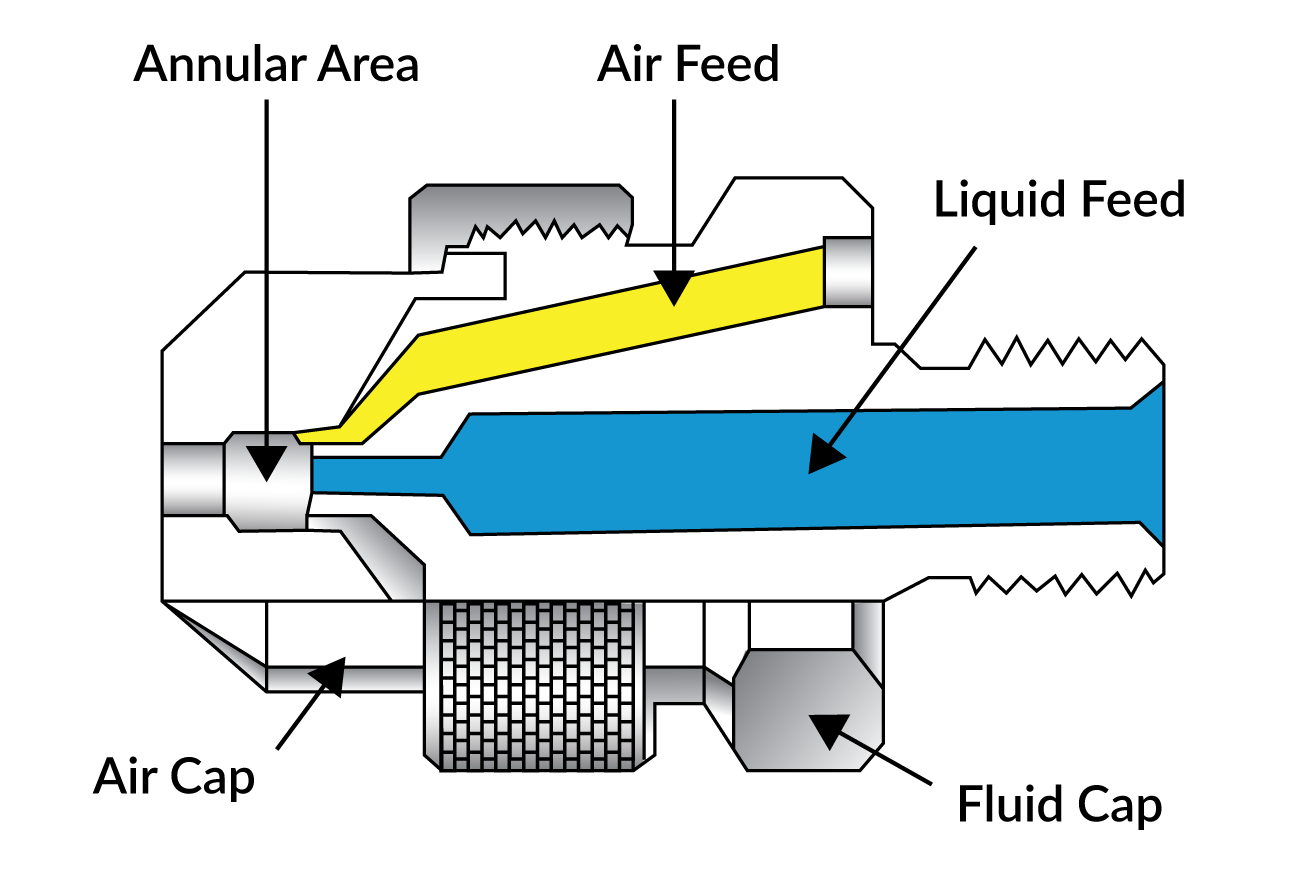

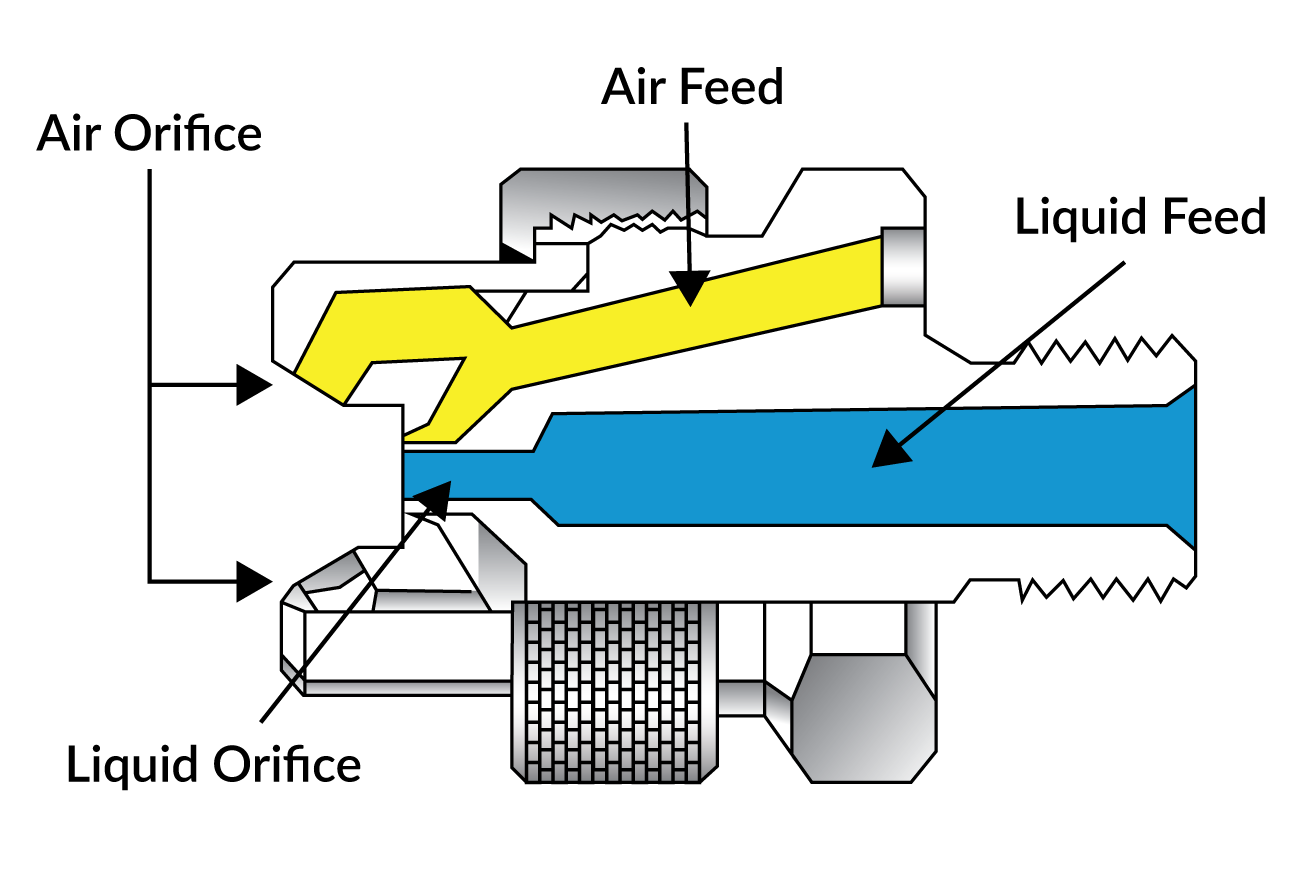

Air atomizing nozzles atomize fluids by combining liquid and compressed air/gas at low pressures to form a very fine spray. They can create either a fan or cone spray pattern depending on the design of the nozzle. There are two methods of mixing fluid and air: internal and external.

Internal Mixing

- Liquid and air streams come together inside the nozzle and are mixed, and they exit through the same orifice.

- The streams are not independent; airflow changes will affect the liquid flow.

- Not suitable for viscous liquids above 200 cP.

External Mixing

- The air and liquid streams exit the nozzle independently through each orifice.

- Air and liquid flow rates can be independently controlled, allowing precise fluid metering.

- Suitable for all liquids, including viscous liquids above 200 cP.

Examples of Why You Would Choose This Spray Pattern Over Others

If you have low pressure and require a smaller drop size with a single fluid nozzle, an air atomizing nozzle is ideal.

An air atomizing design is the best option when a viscous fluid needs to be sprayed and atomized, which cannot be sprayed with a single fluid nozzle.

Ideal for coating, cooling, humidifying, gas cooling, lubricating, moistening, misting, and fogging.

Nozzle Spray Videos

Pressure-fed, internal mix, wide angle, low flow Nozzle: BETE XAAD 150A

Air Atomizing Flat Fan Nozzle: BETE XAEF 350E

Air Atomizing Nozzle, Pressure-fed, Internal Mix BETE XAPR 150A