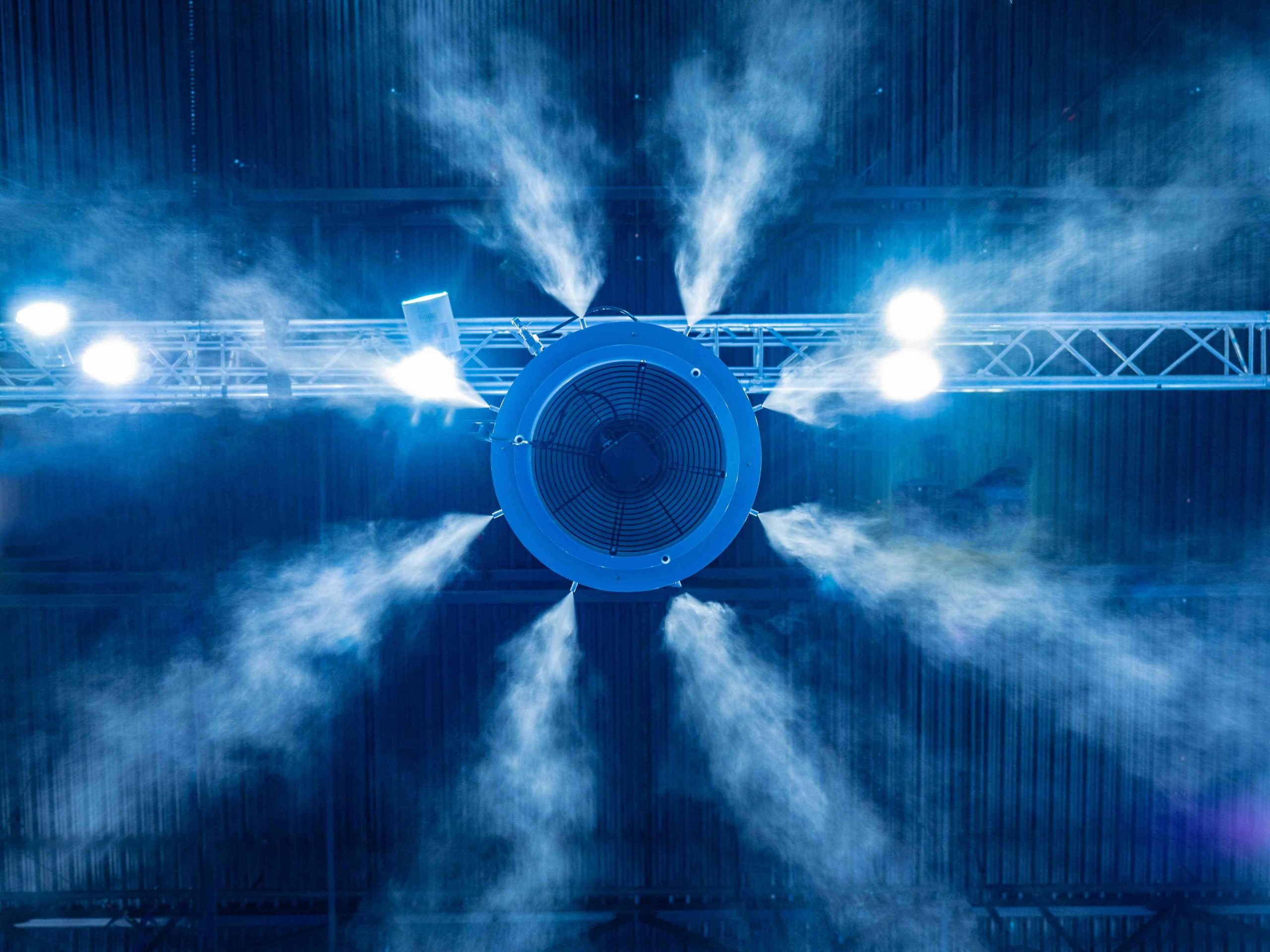

Applications

BETE spray technology is used in a variety of applications and industries including energy, water treatment, chemical processing, petrochemical processing, and food and beverage processing.

Select your application below to discover how BETE can help optimize your process. If you don’t see your application listed, please contact us.

Remove VOCs and THMs from contaminated water

Solutions for cooling inlet air streams with misting nozzles

Prevent corrosion and scale build-up with spray injectors

Spray technology for conveyor cleaning, parts washing, produce washing, and more

Achieve uniform spray coverage and minimal waste for coating

Spray technology for flue gas desulfurization (FGD) and HCL/SO2 removal

Solutions for removing liquids or residues from surfaces

Reduce and control dust in areas, on conveyors, and transfer points

Dispose of excess water with evaporative cooling nozzles

Protect equipment with cooling, evaporation, and wetting

Fire protection of ship decks, cargo, and tanker vessels

Minimize damage to water-sensitive equipment or other assets and for halon replacement

Shield personnel and equipment against radiant heat, harmful gases, and flames

Remove toxic pollutants from exhaust gases in refineries, incinerators, and power plants.

Control foam in water basins, mixing vessels, and more

Solutions for controlling gases and improving pollution control

Remove pollutants and contaminants from process gasses, liquids, and equipment

Increase or add humidity in ducts, chambers, or rooms

Achieve precision lubrication on conveyors, gears, and machine parts

Remove sulfur oxides from ship exhaust gases (FGD)

Control NOx emissions with ammonia or urea injection

Spray odor-neutralizing agents

Distribute fluids evenly over packing materials in scrubbers

Effective methods to reduce temperatures of components and parts

Improve snowmaking process with nucleation nozzles

Solutions to produce spray-dried powders

Improve mixing, blending, and agitating with eductor nozzles

Spray technology to help contain water-soluble, toxic gases from the air

Precisely distribute process fluids into vacuum distillation units

Remove fly ash and particulates from gas streams

Wash contaminants from gas streams and piping components with spray injection