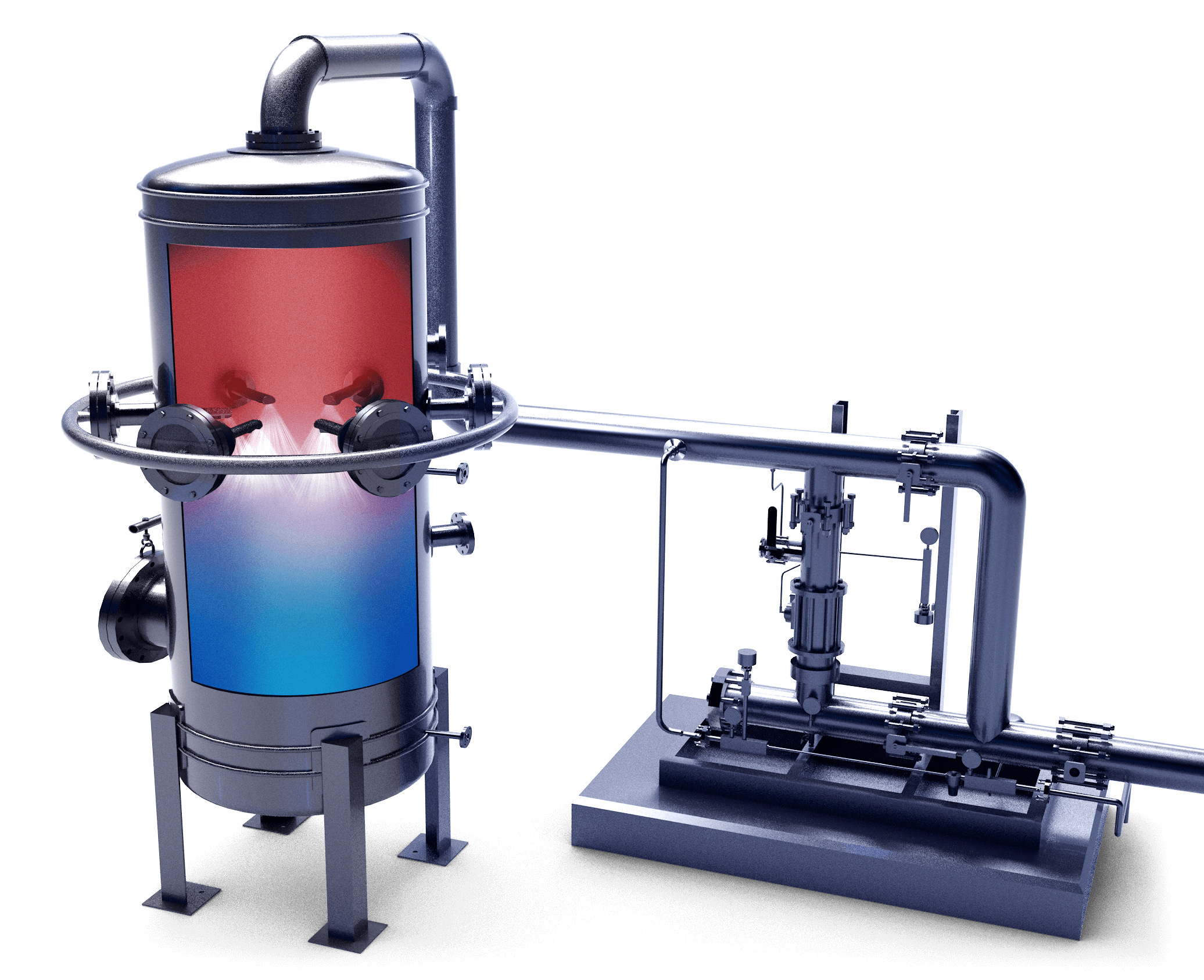

BETE spray nozzles and spray systems are used for gas cooling and conditioning to improve processes in chemical processing, petrochemical plants, cement plants, and more. BETE’s air quality and pollution control systems provide engineered solutions by combining nozzles and lances designed for improving your process.

In many processes, gas is raised to temperatures that could easily damage downstream equipment. Gas can either come from direct combustion, as in the case of flue gas, or by secondary heating. The quickest and most effective way to cool a hot gas is to evaporate an injected liquid. Changing the phase of the injected liquid to gas consumes enormous amounts of energy compared to sensible/direct contact cooling.

As an example, heating water from 32 °F to 212 °F (0 °C to 100 °C) requires about 180 BTU/LBM (418 kJ/kg). Converting that same water from liquid at 212 °F (100 °C) to steam at 212 °F (100 °C) requires about 1000 BTU/LBM (2320 kJ/kg), or more than five times the energy. The energy used to vaporize the gas is taken from the hot gas, thus lowering its temperature.

In evaporative gas cooling, a water mist is sprayed into the hot gas. In many cases, this is flue gas from a combustion process. The water then evaporates, cooling the system rapidly as the energy changes the water from liquid to gas. When a volume of water is atomized into smaller droplets, more surface area is exposed, increasing the evaporation rate. The evaporation rate is often critical as the gas must reach its final temperature before a fixed point downstream. The evaporation rate is dependent on the droplet size, temperature differential, and partial pressure, among other variables.

Common Uses And Industries

Important factors to consider:

Initial/final process gas temperatures

Process gas composition (including initial water content)

Available residence time for droplet evaporation

Available and required flow rate

Available pressure drop (∆P) across the nozzle

- ∆P = supply pressure at nozzle inlet – process pressure outside nozzle

Required coverage

- Ensure complete contact/cooling of a gas stream while minimizing potential wall contact

Required droplet size

- Achieve complete or partial evaporation to obtain the required cooling

Required nozzle material

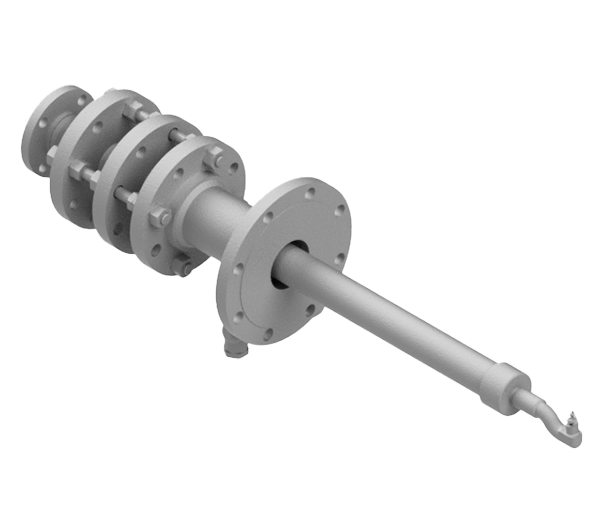

- Quench nozzles often require special materials to withstand the high temperature and corrosive environments present in these applications