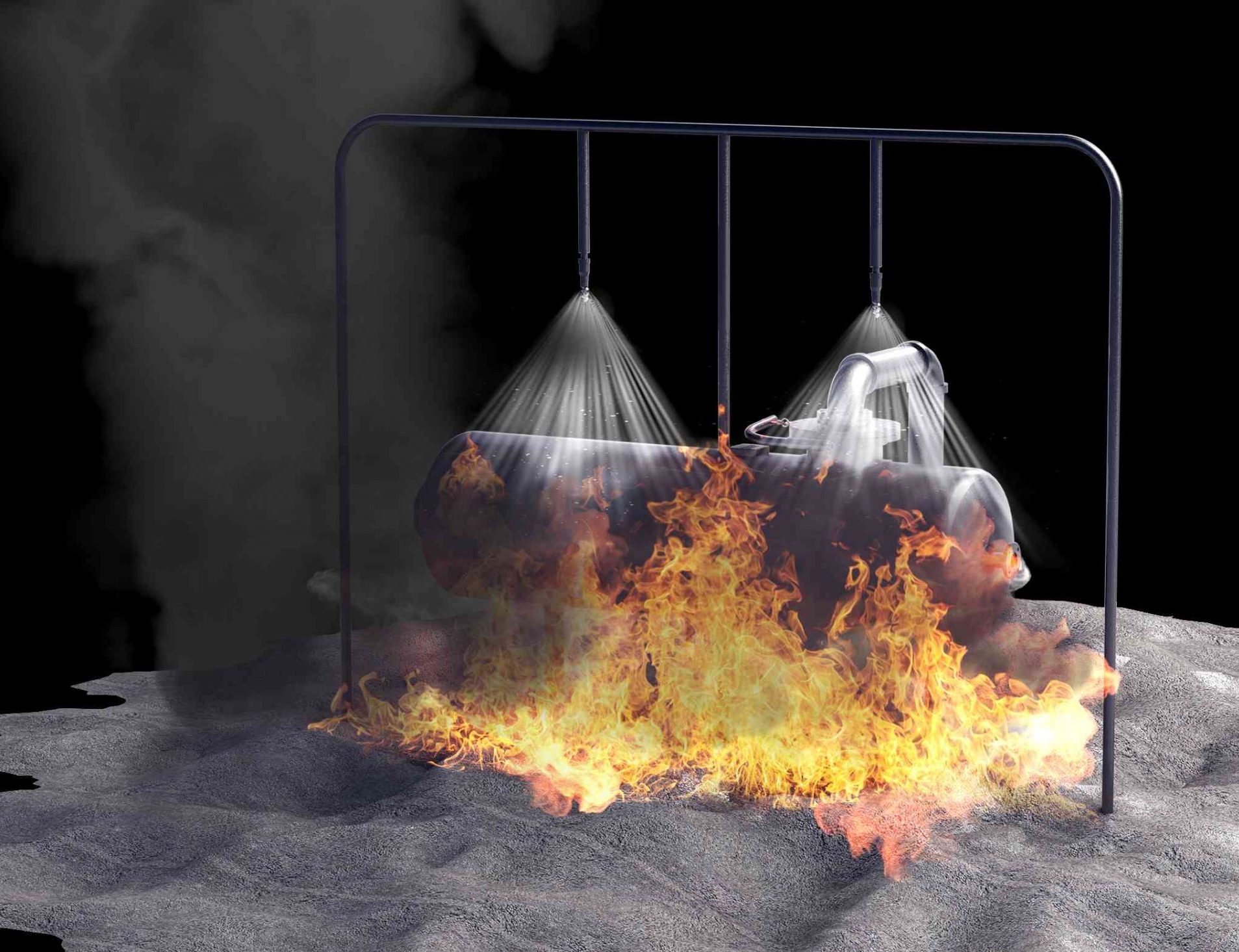

Open-type water spray protection systems are typically designed per NFPA 15 or similar design standards and are acceptable for protecting against hazards involving; flammable or combustible materials, electrical hazards, propellants, pyrotechnics, and similar life/safety situations. BETE spray nozzles are used for cooling, evaporation, and wetting in water deluge systems.

Open-type deluge nozzles and systems typically maintain dry supply piping. With the use of heat, smoke, or flame detection equipment, a deluge valve opens and supplies water and pressure to the nozzle for operation. These differ from automatic systems in which automatic nozzles use a heat-sensitive element to maintain a closed orifice and retain the water/pressure of the supply piping system until activated.

Common Uses And Industries

Important factors to consider:

Size & shape of the target area, equipment, or enclosure

Applicable design specifications and requirements

- Required flow rates/coverage densities

Available nozzle mounting locations

Available pressure drop (∆P) across the nozzle

- ∆P = supply pressure at nozzle inlet – process pressure outside nozzle

As a nozzle manufacturer, BETE Fog Nozzle, Inc. cannot assume responsibility for the design of life/safety systems