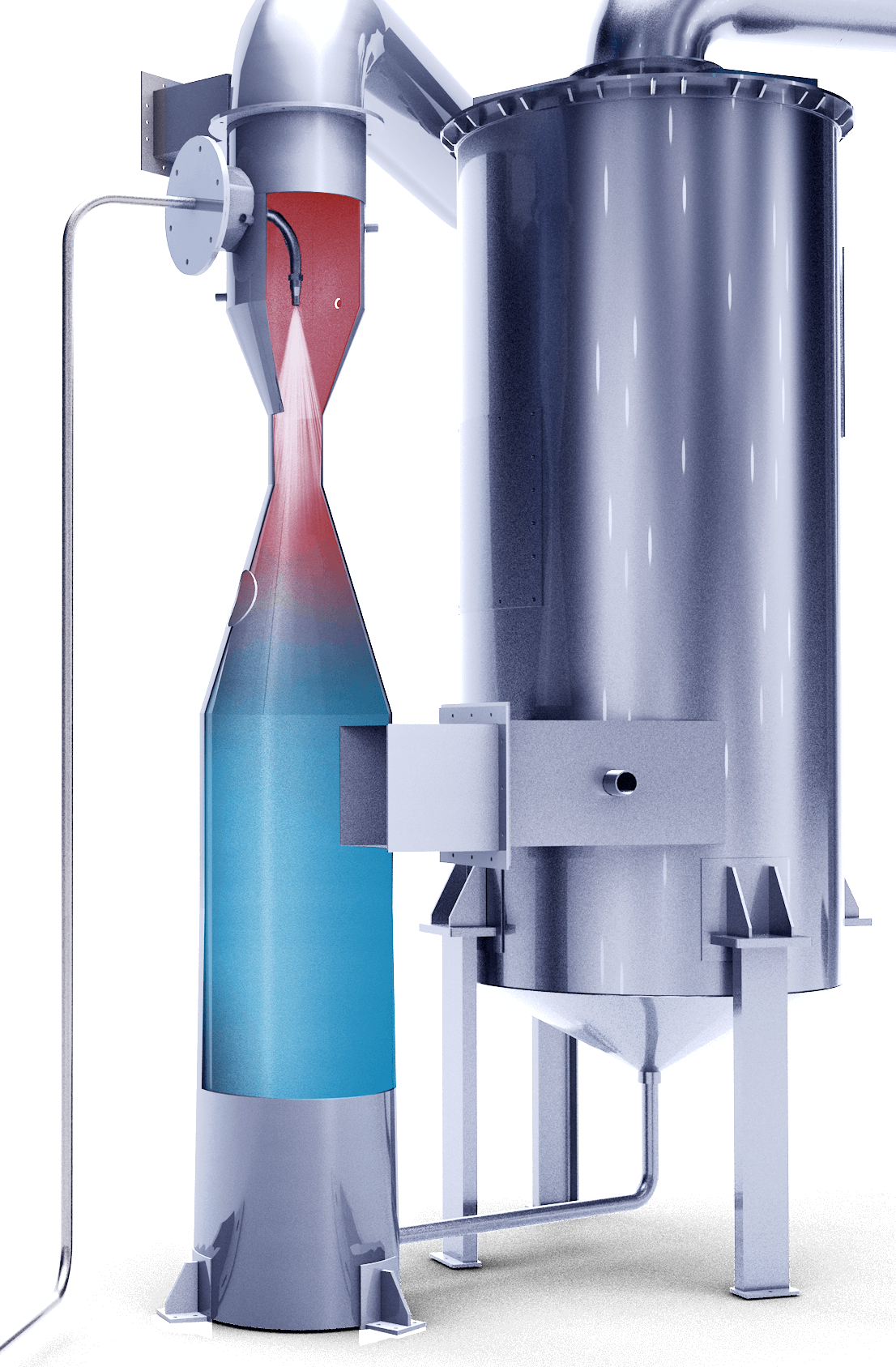

Scrubber nozzles remove pollutants and other chemical contaminants from process gases, liquids, and equipment. Scrubbers can remove sulfur oxides (SOx) from boiler exhaust in coal-fired power plants, nitrous oxides (NOx) from combustion streams, acids from chemical processing off-gases, disinfectants from drinking water, particulates from the process gas, and odors from water treatment plants, among many other potential uses.

While there are many specific types and uses for scrubbers, they typically fall under two general categories of basic scrubber designs:

- Open Scrubbers: These nozzles are designed to spray the scrubbing liquid directly into the process stream. Open scrubbers depend on the correct droplet size and process conditions to maximize the reaction or mass transfer rate. These are usually dependent on the droplets’ surface area to volume ratio.

- Packed Scrubbers: These nozzles work by spraying a scrubbing fluid over a packing material within a tower, with an upward or horizontally flowing gas stream passing through the packing. The packing becomes saturated with the liquid and creates a film for the gas/liquid interaction.

MaxiPass® (MP) Maximum Free Passage Full Cone Nozzles

Contact our spray experts to find the perfect nozzle for your application.