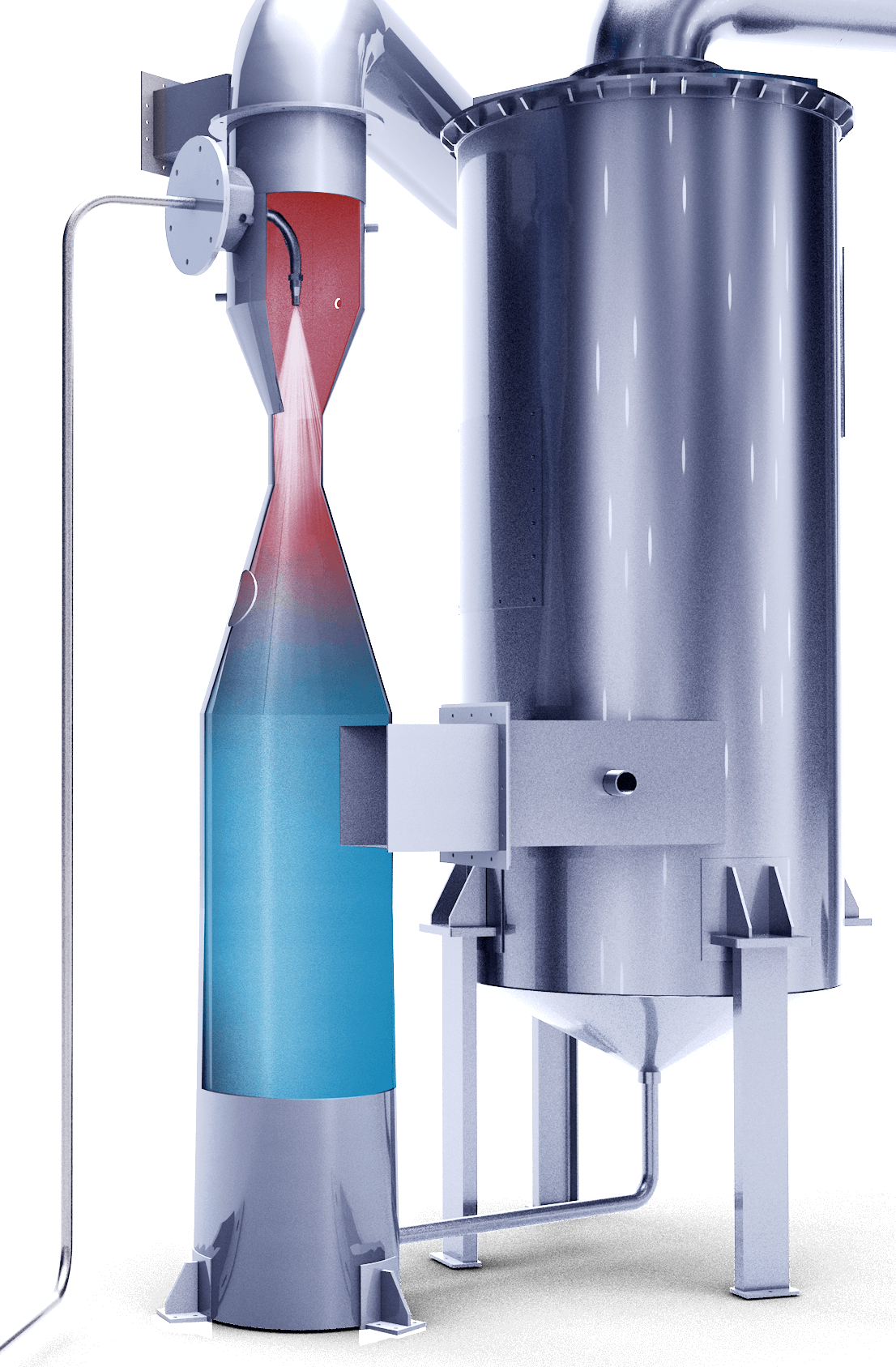

A Venturi scrubber is a wet-scrubbing process that uses direct contact between the gas to be scrubbed and the liquid agent. It derives its name from and utilizes the Venturi effect, in which a fluid increases its velocity as the area through which it is flowing decreases.

In Venturi scrubbing, the gas to be scrubbed flows through a duct that narrows in cross-section, increasing the gas’s velocity. Water or other scrubbing fluids are usually sprayed axially into the narrowest section of the duct, known as the throat, with the spray sized to fit the cross-section of the duct. The shear forces applied to the droplets caused by the high velocity, turbulent air atomizes the water quickly and provides effective mixing allowing for better gas to liquid contact. This condition causes highly efficient particle collection and can be used for certain gas scrubbing applications. The high-velocity axial spray can draw the gas stream through this scrubbing section. It eliminates the need for additional gas moving fans or blowers. Downstream of the narrow section, the duct expands back to its original size, and the liquid with the contaminants is removed from the gas stream and collected/filtered.

Common Uses & Industries

Important factors to consider:

Scrubber size, velocity, pressure, temperature, and fluid composition

Nozzle mounting location and orientation

Required coverage

Required materials of construction for corrosive environments

Spray media density and viscosity

Required scrubbing fluid flow rate

Available pressure drop (∆P) across the nozzle

- ∆P = supply pressure at nozzle inlet – process pressure outside nozzle