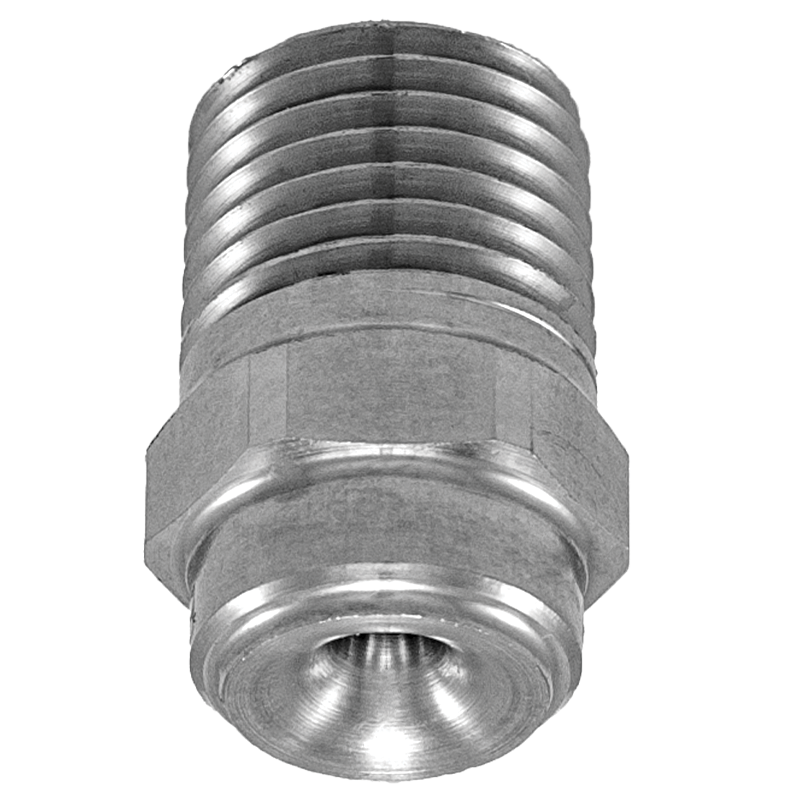

Improve and extend snow conditions by spraying water in a cold environment, growing a snow crystal, and blowing the resulting snow where desired. The water sprayed from an atomizing nozzle creates a fog of tiny water droplets, and these microdrops quickly freeze to form the nucleus of a snowflake.

Secondary nozzles generate slightly larger water droplets that adhere and freeze to the nucleus created by the spray from the primary nozzle. These secondary nozzles do not need fine atomization. Throughout the process, a compressor or blower pushes cold air past the nozzles in the snowmaking assembly and propels the snow out of the snow gun.

Common Uses And Industries

Important factors to consider:

Equipment specifications and requirements

- Tower Guns

- Fan Guns

- Air/water mixtures

- Two-phase flow effects on spray nozzle performance

Available air and water flow rates

Available air and water operating pressures

Required spray patterns/coverage