DESIGN FEATURES

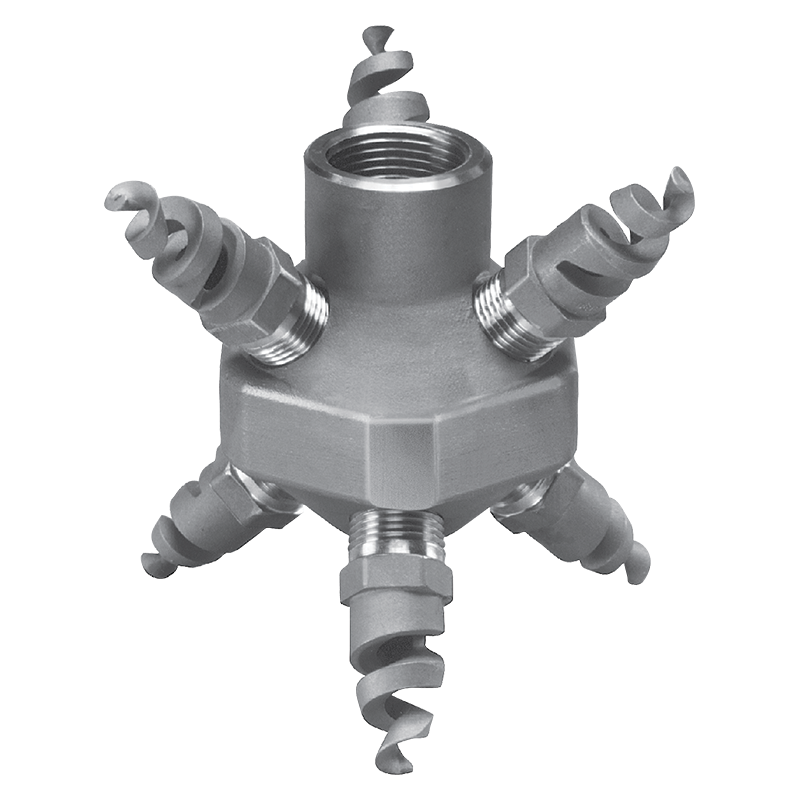

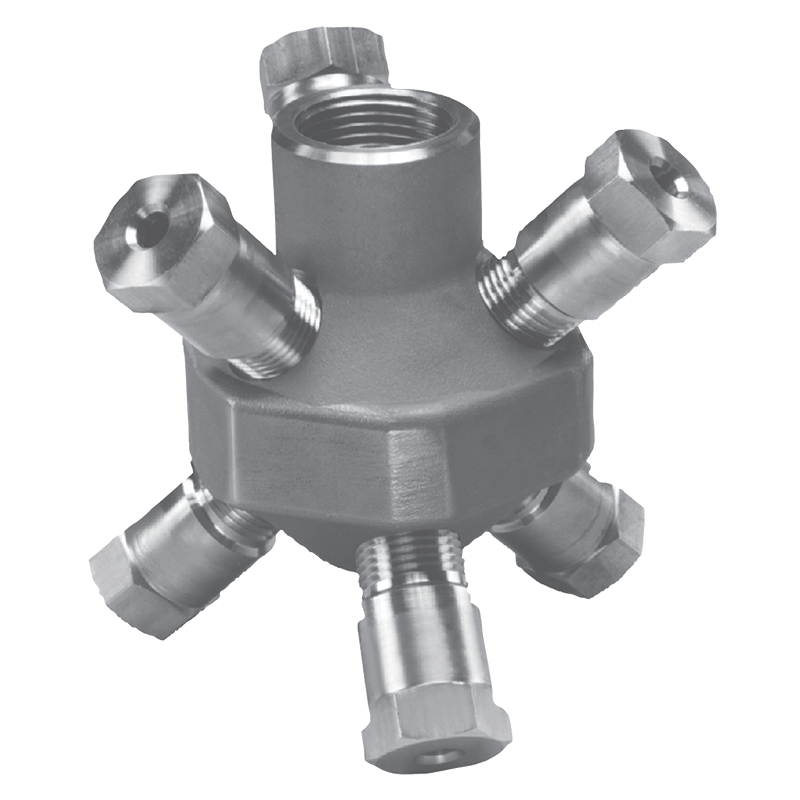

Spray nozzle heads for industrial tank cleaning, drum, and tote washing

Six clog-resistant MaxiPass® full cone nozzles arranged in a cluster to project spray in all directions

Can be supplied with various BETE nozzles for any desired application

Spherical omnidirectional coverage

HOW SPRAY PATTERN IS ACHIEVED

A manifold distributes water to several standard full cone nozzles with orientations positioned to achieve a full omnidirectional spray coverage

Available Spray Angle

360°

Flow Rate Range

7.38 to 124 gpm

Available Connection Types

- Pipe: 3/4, 1

- Connection Methods: Thread (NPT, BSP, Female)

Materials

Brass, 316, A494 CW2M (cast Nickel Alloy C-276)

Flow Rates, Spray Angles, Connections

Tank Cleaning

Select a nozzle number below for performance graph, drawings, and to request a quote.

Flow rate (gpm/lpm) is calculated at differential pressure (psi/bar).

Nozzle Number

Connection Sizes

Spray Angles

Flow Rate (gpm) @ Differential Pressure (psi) (Density: 1 SG)

10 psi

20 psi

30 psi

40 psi

50 psi

60 psi