DESIGN FEATURES

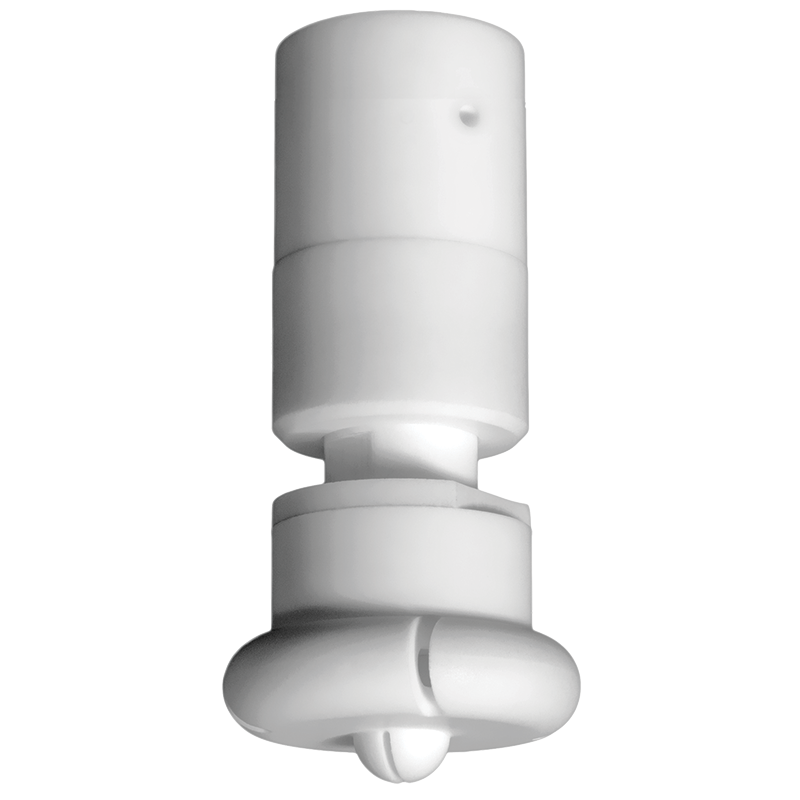

Improve efficiency and reduce waste with HWS2 rotating spray heads designed to clean IBC totes, drums, barrels, and mid-size industrial or hygienic tanks

Cleans faster and uses less water and lower pressure than static spray balls

Unique patent-pending pipe thread technology flushes to reduce contamination and bacteria growth

Zirconia ceramic bearings for long service life and extreme chemical resistance

Corrosion resistant FDA-compliant 316 stainless steel construction

32 Ra surface finish ideal for sanitary applications

Patent-pending no-weld design eliminates weak points and uneven surfaces

Self-cleaning bearings centered within the spray head for improved balance and spray propagation

Compact size with industry-leading flow rates fits 3/4”- 2” tri-clamp openings

Operates in any direction

HOW SPRAY PATTERN IS ACHIEVED

The HydroWhirl Stinger tank cleaning nozzle directs the cleaning water through a rotating head at the tip of the spray assembly and produces a vigorous moving spray action against all areas of the walls of a tank.

The spray pattern from the HydroWhirl Stinger head uses impact and repetition to wash the tank quickly.

- Tube: 3/8in, 1/2in, 3/4in, 1in

- Pipe: 1/8, 3/8, 1/2, 3/4, 1

- Connection Methods: Clip-on, Thread (NPT, Female)