DESIGN FEATURES

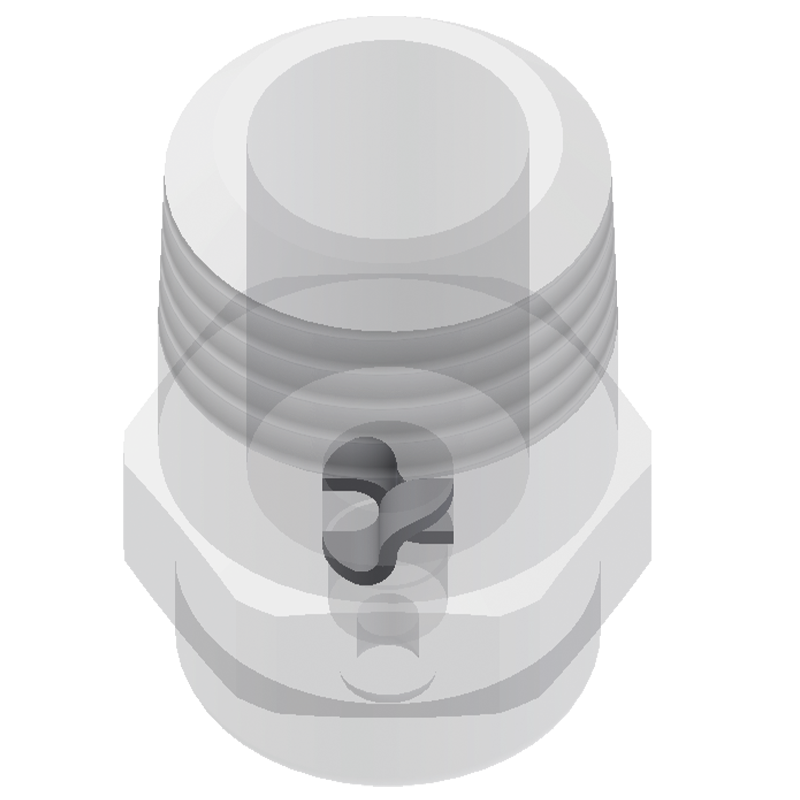

Ultimate clog-resistant design with largest free passage available in a full cone nozzle

Two unique S-shaped internal vanes, as opposed to x-vane style nozzles, allow maximum free passage of particles

Vanes are made from 316SS for optimum wear and corrosion resistance

High energy efficiency

Easily handles dirty, contaminated liquids

High-reliability spray performance under the most difficult conditions

HOW SPRAY PATTERN IS ACHIEVED

Atomization is achieved by the water being spun inside the nozzle and then exiting an orifice

Produces medium to coarse droplet size

More uniform pattern than spiral nozzles

Available Spray Angles

51 - 134°

Flow Rate Range

0.0859 to 3.02 gpm

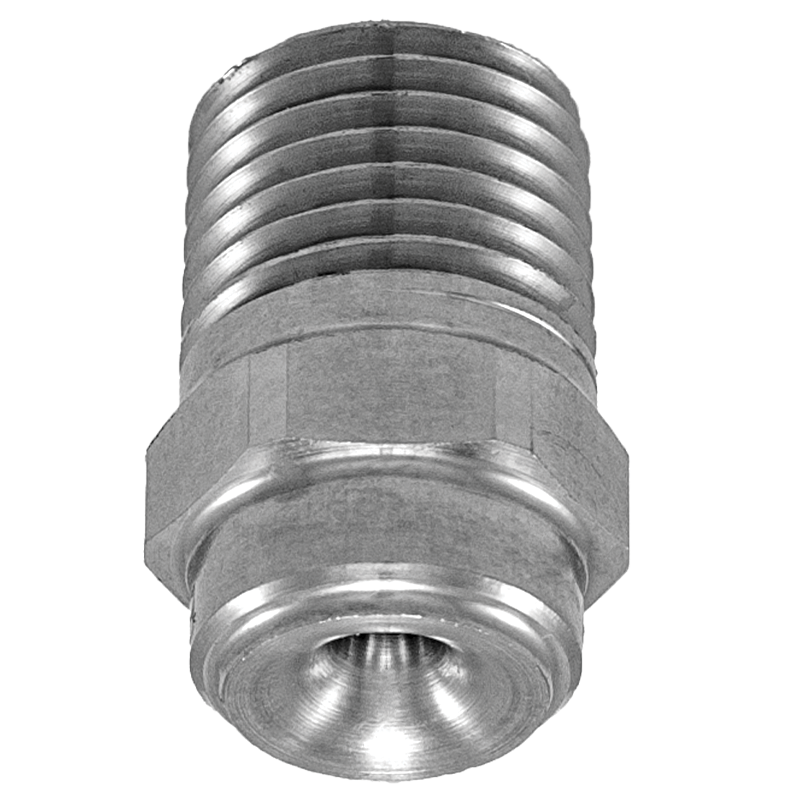

Available Connection Types

- Pipe: 1/8, 1/4

- Connection Methods: Thread (NPT, BSP, Male)

Materials

Brass, 303, 316

Flow Rates, Spray Angles, Connections

Full Cone

Select a nozzle number below for performance graph, drawings, and to request a quote.

Flow rate (gpm/lpm) is calculated at differential pressure (psi/bar).

Nozzle Number

Connection Sizes

Spray Angles

Flow Rate (gpm) @ Differential Pressure (psi) (Density: 1 SG)

10 psi

20 psi

40 psi

50 psi

60 psi

80 psi

0.116

0.156

0.210

0.231

0.250

0.283

0.164

0.221

0.298

0.328

0.355

0.401

0.231

0.312

0.420

0.462

0.500

0.566

0.315

0.424

0.572

0.629

0.680

0.770

0.425

0.573

0.772

0.850

0.919

1.04

0.616

0.830

1.12

1.23

1.33

1.51

0.832

1.12

1.51

1.66

1.80

2.03