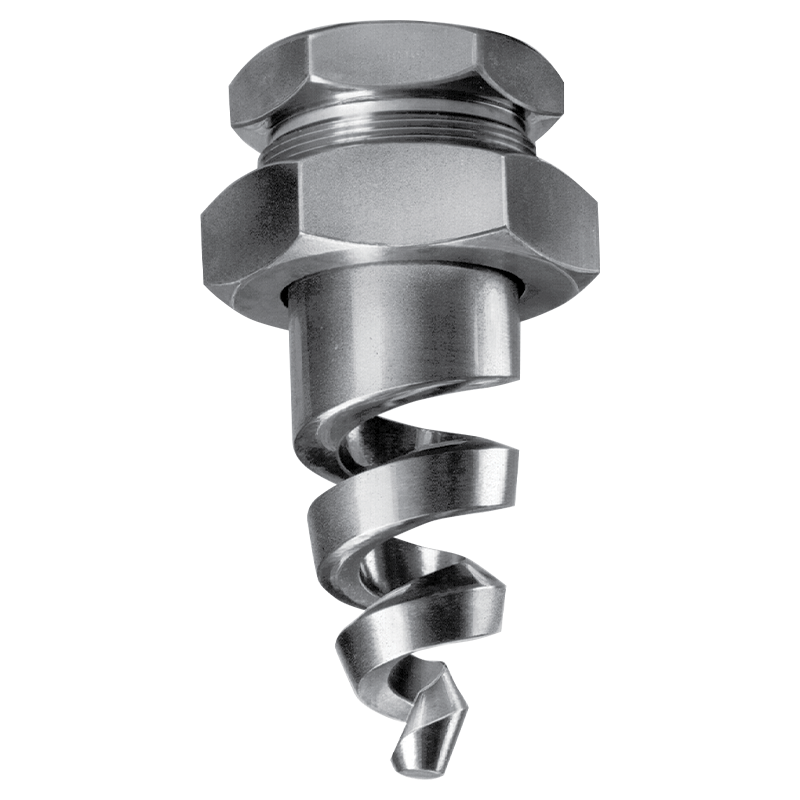

DESIGN FEATURES

Clog-resistant spiral design

Energy-efficient; uses less water than conventional designs

Compact design; fits small openings

Easy to maintain

Unique patterns that spray in opposing directions

HOW SPRAY PATTERN IS ACHIEVED

The spray pattern of the spiral nozzle is formed by the fluid shearing along with the turns of the spiral, which produce multiple concentric cones. These cones form 2 to 3 bands of relatively coarse droplets, surrounded by wider bands of relatively fine droplets.

Available Spray Angles

180 - 270°

Flow Rate Range

3 to 114 gpm

Available Connection Types

- Pipe: 3/8, 1

- Connection Methods: Thread (NPT, BSP, Male)

Materials

Brass, 316, A494 CW2M (cast Nickel Alloy C-276)

Flow Rates, Spray Angles, Connections

Tank Cleaning

Select a nozzle number below for performance graph, drawings, and to request a quote.

Flow rate (gpm/lpm) is calculated at differential pressure (psi/bar).

Nozzle Number

Connection Sizes

Spray Angles

Flow Rate (gpm) @ Differential Pressure (psi) (Density: 1 SG)

10 psi

20 psi

40 psi

50 psi

60 psi

100 psi