DESIGN FEATURES

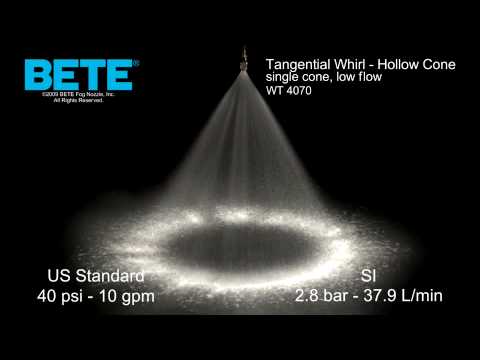

Conventional design using tangential whirl method of atomization

Durable

Use where a circular pattern is required or in a large area with multiple installations where there is considerable overlapping of sprays

Large free passage

HOW SPRAY PATTERN IS ACHIEVED

Tangential hollow cone nozzles utilize a supply of liquid perpendicular to the direction of spray. Flow enters a swirl chamber without the use of internal components —allowing for maximum clog resistance.

Available Spray Angles

70 - 125°

Flow Rate Range

0.0353 to 37.9 gpm

Available Connection Types

- Pipe: 1/8, 1/4, 3/8, 1/2, 3/4

- Connection Methods: Thread (NPT, BSP, Male, Female)

Materials

Brass, 303, 316, Duplex 2205, Nickel Alloy C-276, Nickel Alloy C-22, Nickel Alloy 625, Nickel Alloy 825

Flow Rates, Spray Angles, Connections

Hollow Cone

Select a nozzle number below for performance graph, drawings, and to request a quote.

Flow rate (gpm/lpm) is calculated at differential pressure (psi/bar).

Nozzle Number

Connection Sizes

Spray Angles

Flow Rate (gpm) @ Differential Pressure (psi) (Density: 1 SG)

5 psi

10 psi

20 psi

40 psi

60 psi

100 psi

0.0353

0.0500

0.0707

0.0999

0.122

0.158

0.0425

0.0601

0.0850

0.120

0.147

0.190

0.0637

0.0901

0.127

0.180

0.221

0.285

0.0707

0.0999

0.141

0.200

0.245

0.316

0.0955

0.135

0.191

0.270

0.331

0.427

0.124

0.175

0.247

0.350

0.428

0.553

0.141

0.200

0.283

0.400

0.490

0.632

0.148

0.210

0.297

0.420

0.514

0.664

0.170

0.240

0.339

0.480

0.588

0.759

0.177

0.250

0.354

0.500

0.613

0.791

0.187

0.265

0.375

0.530

0.649

0.838

0.212

0.300

0.424

0.600

0.735

0.949

0.241

0.342

0.483

0.683

0.837

1.08

0.248

0.351

0.496

0.702

0.860

1.11

0.282

0.398

0.563

0.797

0.976

1.26

0.353

0.500

0.707

0.999

1.22

1.58

0.461

0.651

0.921

1.30

1.60

2.06

0.530

0.749

1.06

1.50

1.84

2.37

0.566

0.800

1.13

1.60

1.96

2.53

0.637

0.901

1.27

1.80

2.21

2.85

0.707

0.999

1.41

2.00

2.45

3.16

0.778

1.10

1.56

2.20

2.70

3.48

0.847

1.20

1.69

2.40

2.94

3.79

0.919

1.30

1.84

2.60

3.18

4.11

0.955

1.35

1.91

2.70

3.31

4.27

0.991

1.40

1.98

2.80

3.43

4.43

1.06

1.50

2.12

3.00

3.67

4.74

1.20

1.70

2.41

3.40

4.17

5.38

1.24

1.75

2.47

3.50

4.28

5.53

1.41

2.00

2.83

4.00

4.90

6.32

1.56

2.20

3.11

4.40

5.39

6.96

1.70

2.40

3.39

4.80

5.88

7.59

1.77

2.50

3.54

5.00

6.13

7.91

1.98

2.80

3.96

5.60

6.86

8.85

2.05

2.90

4.10

5.80

7.10

9.17

2.12

3.00

4.24

6.00

7.35

9.49

2.26

3.19

4.52

6.39

7.82

10.1

2.41

3.42

4.83

6.83

8.37

10.8

2.82

3.98

5.63

7.97

9.76

12.6

3.53

5.00

7.07

9.99

12.2

15.8

4.25

6.01

8.50

12.0

14.7

19.0

4.94

6.99

9.88

14.0

17.1

22.1

5.66

8.00

11.3

16.0

19.6

25.3

6.37

9.01

12.7

18.0

22.1

28.5

7.07

9.99

14.1

20.0

24.5

31.6

7.78

11.0

15.6

22.0

27.0

34.8

8.47

12.0

16.9

24.0

29.4

37.9