Quick Product Search

All Categories

Accessories & Special Purpose

Air Atomizing Nozzles

Automated Spray Systems

Automatic Nozzles

Fan Nozzles

Fire Protection Nozzles

Full Cone Nozzles

Hollow Cone Nozzles

Misting Nozzles

Spiral Nozzles

Spray Drying Nozzles

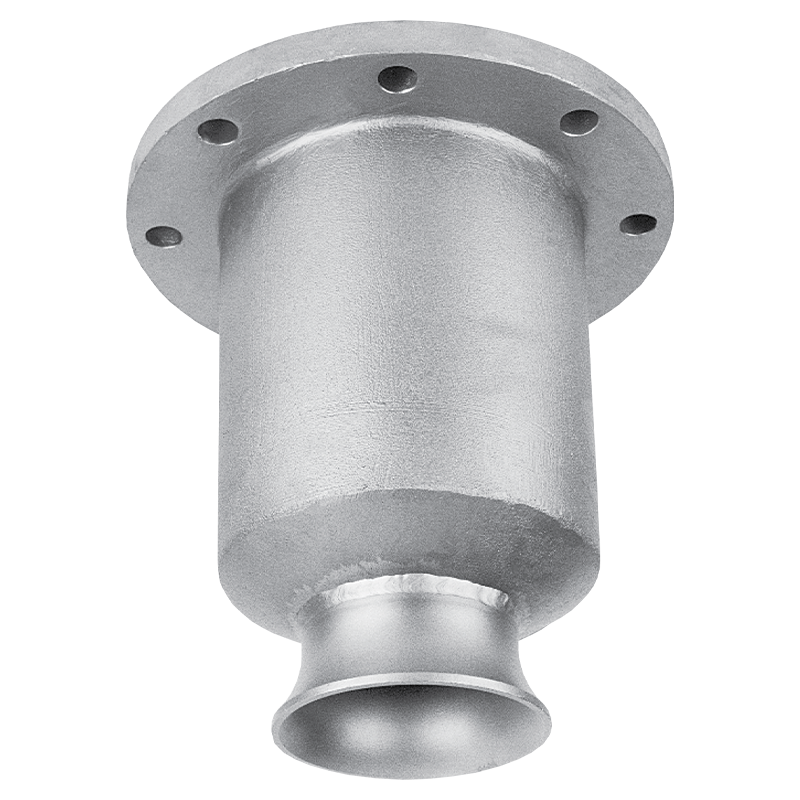

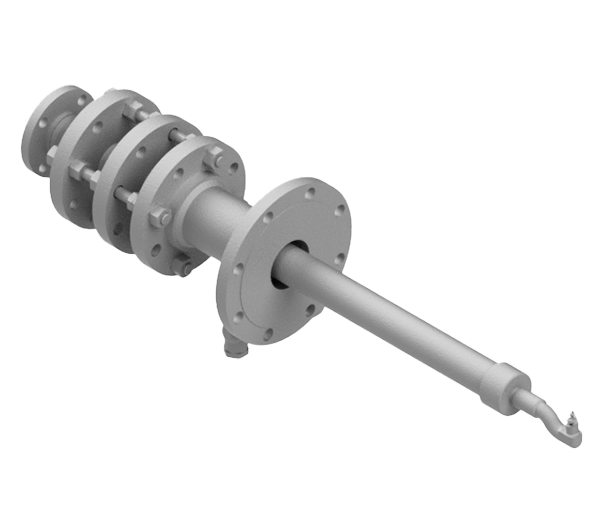

Spray Headers, Spargers & Spools

Spray Lances, Injectors & Quills

Tank Cleaning Nozzles

Tank Mixing Nozzles

Loading products....

HydroPulse® EHP Hygienic Precision Spray Automatic Nozzles

Food-Grade Electrically Actuated Intermittent Spray Nozzles

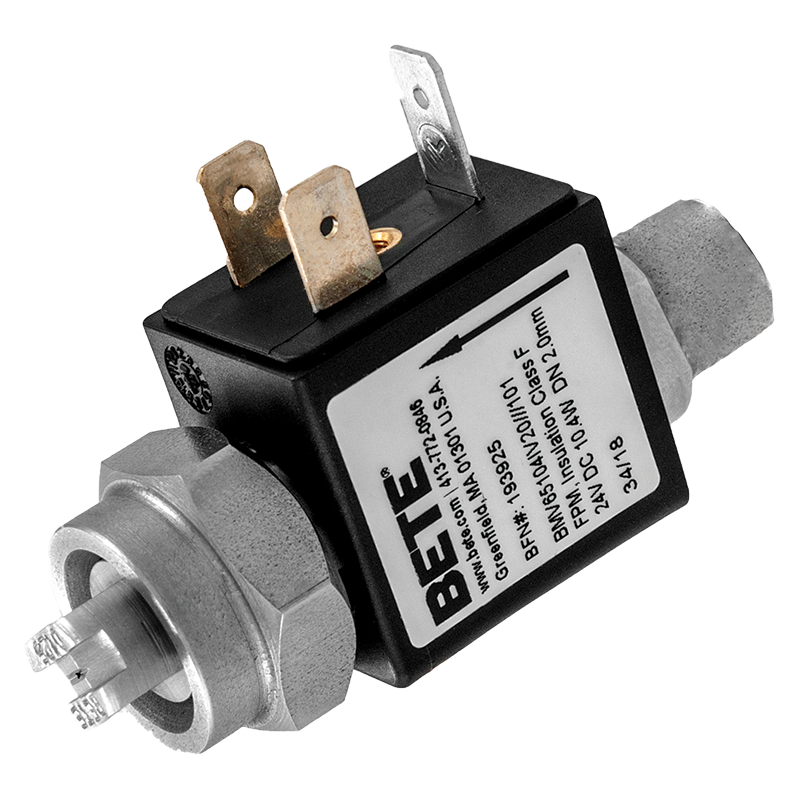

HydroPulse® EHPI Precision Spray Automatic Nozzles

Industrial-Grade Electrically Actuated Intermittent Spray Nozzles

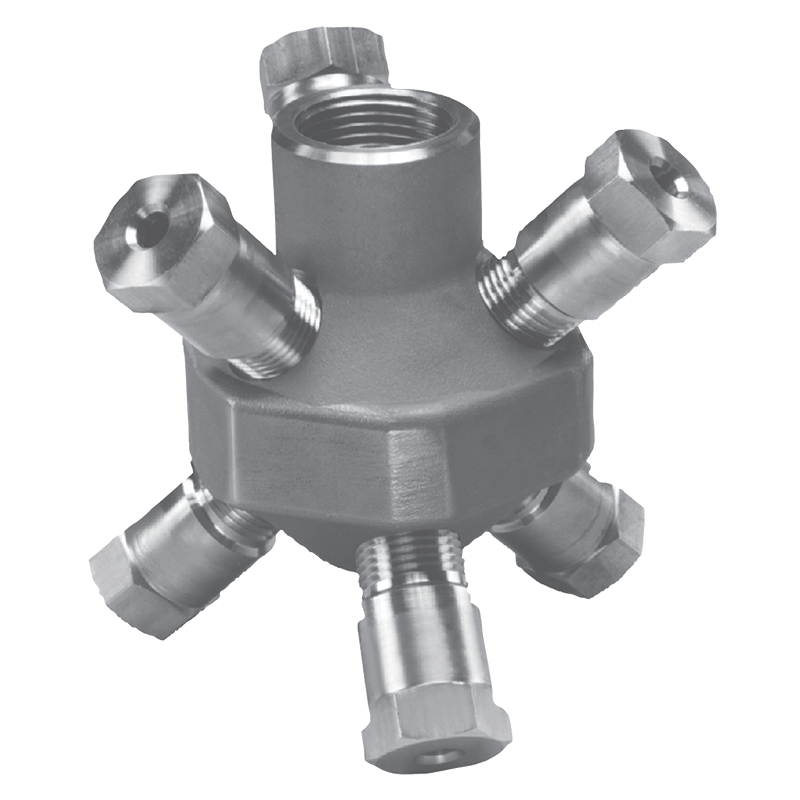

HydroClaw® (HC) Clog-Resistant Tank Cleaning Nozzles

Reduce Down-Time With Patented Stationary Tank Cleaning Devices

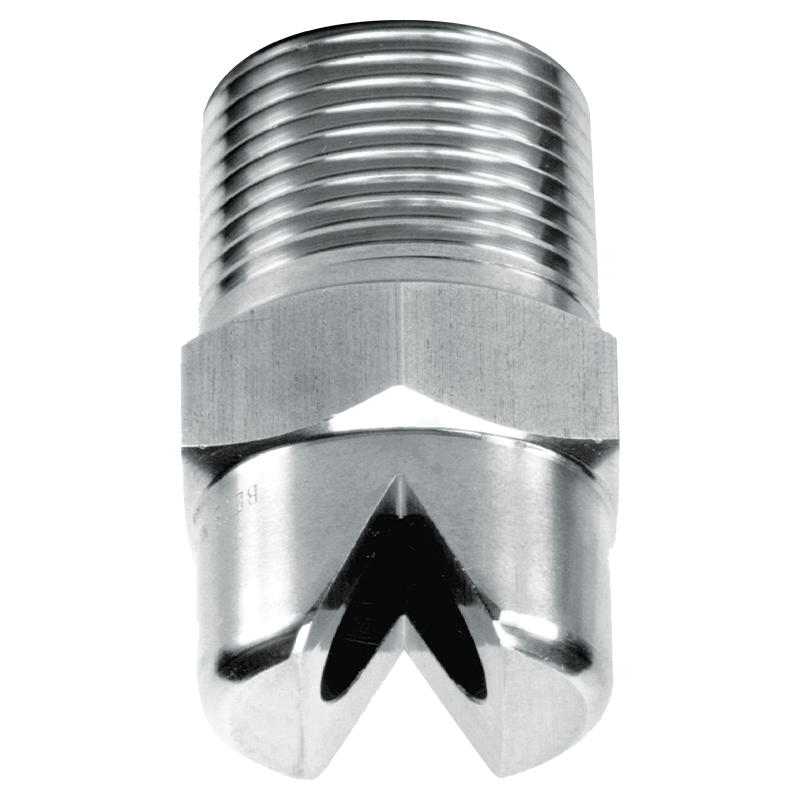

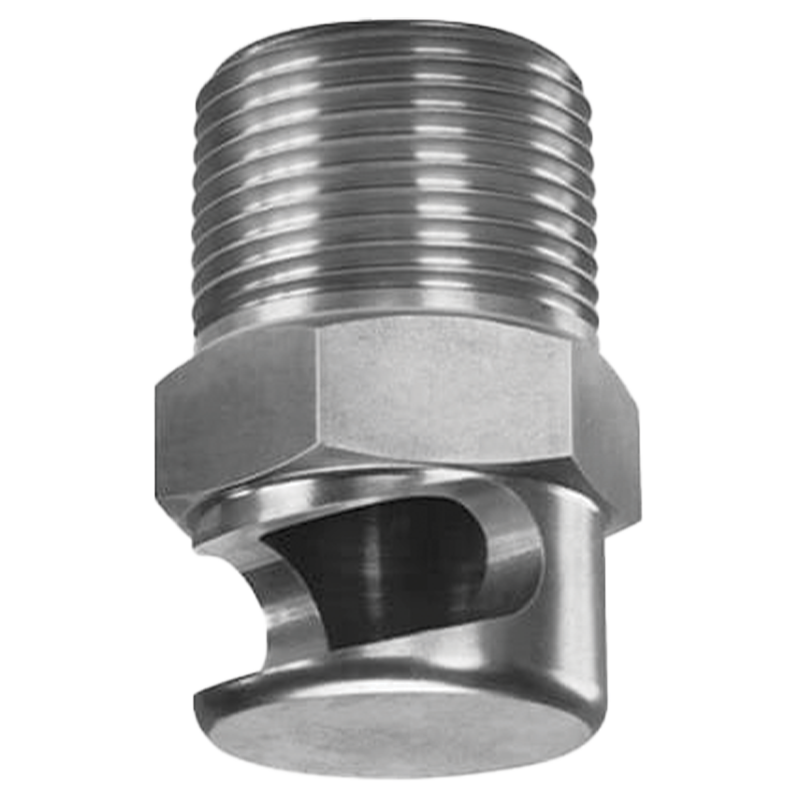

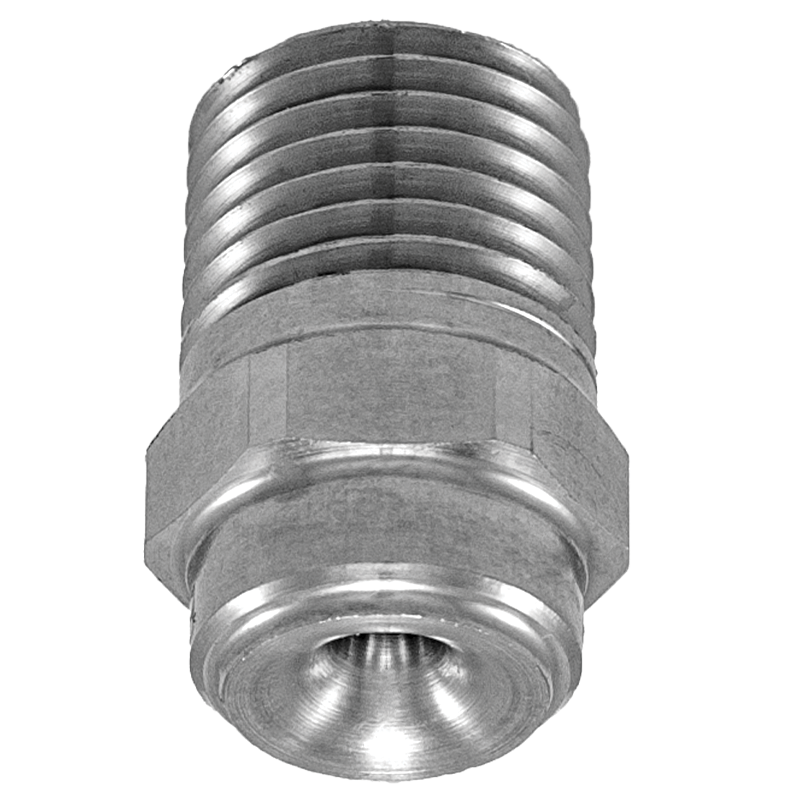

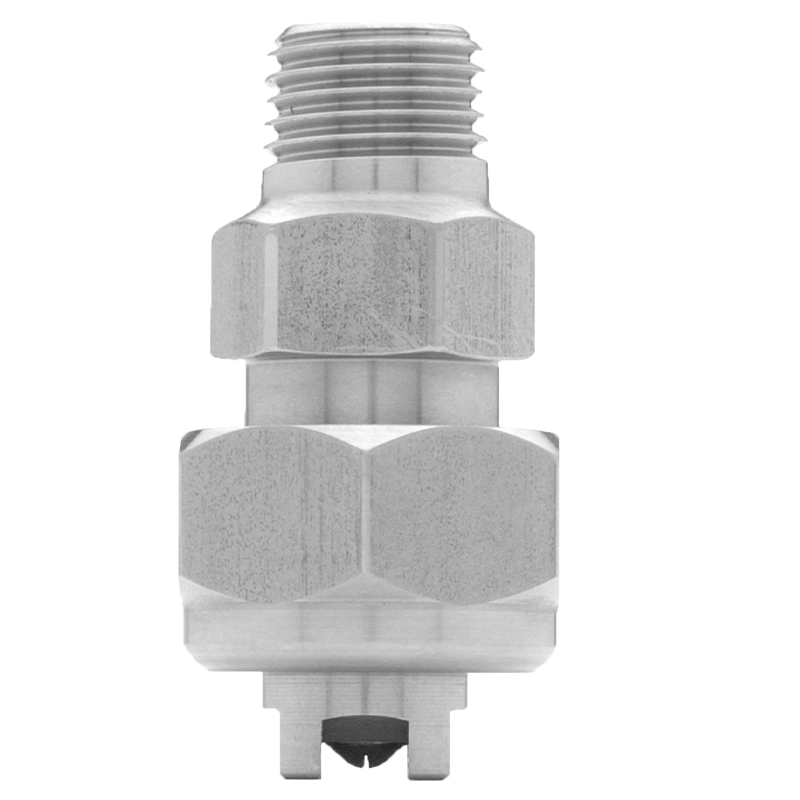

MaxiPass® (MP) Maximum Free Passage Full Cone Nozzles

Ultimate Clog-Resistant Spray Nozzles for Cooling and Quenching

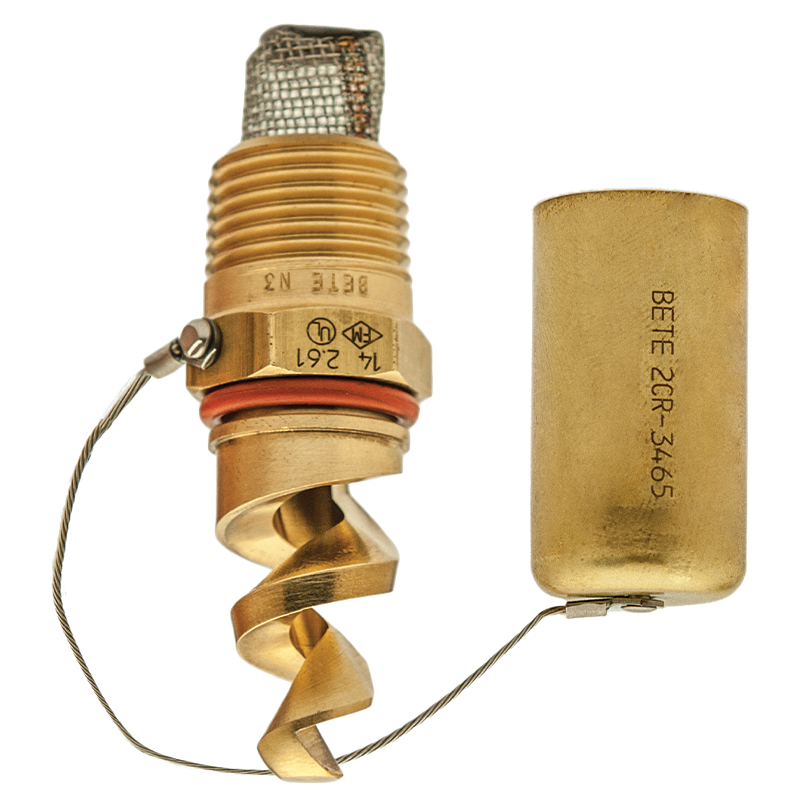

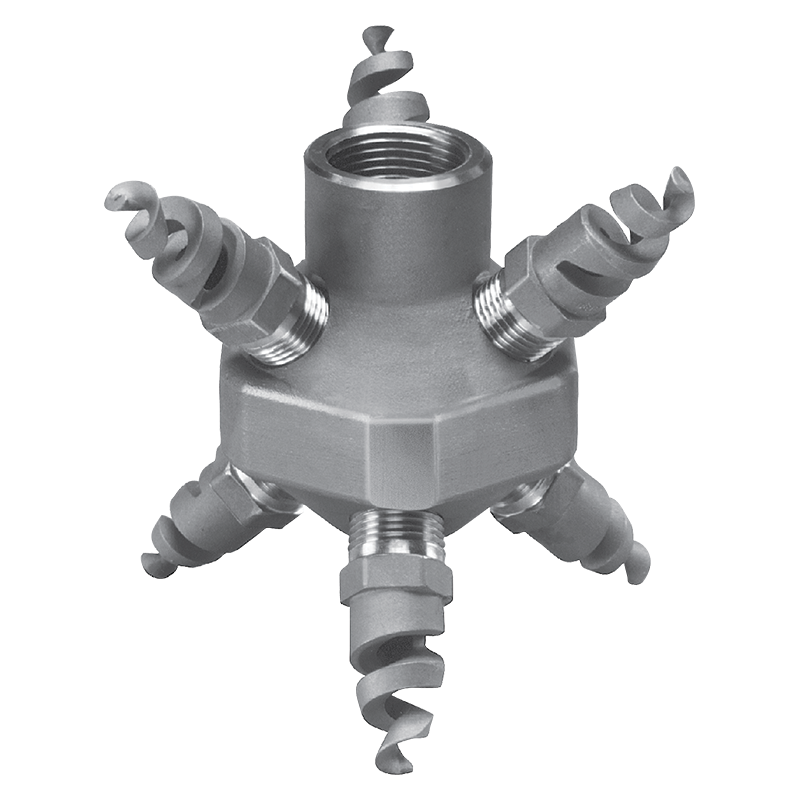

TF Full Cone & Hollow Cone Spiral Nozzles

Original Pigtail Spray Nozzle for Quenching, Scrubbing, and Evaporative Cooling

FlexFlow® Industrial Automated Spray Systems

Precision Spray Control for Coating, Lubricating, and Moistening

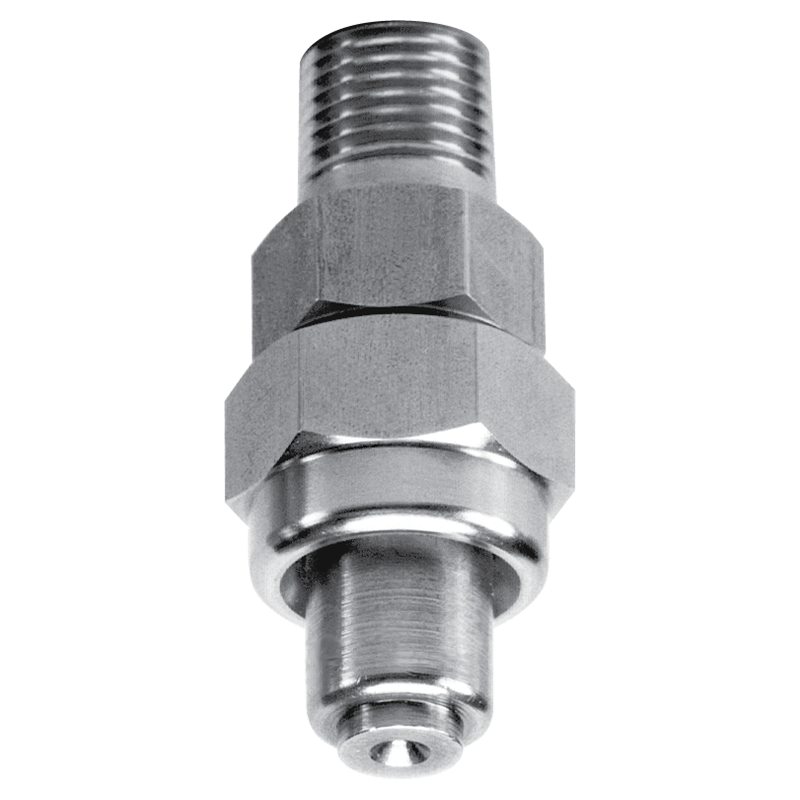

MaxiPass® L (MPL) Low Flow Full Cone Nozzles

Energy-Efficient Axial Spray Nozzles for Cooling & Quenching

HydroWhirl® Orbitor 100 (HWO100) Compact Tank Cleaning Machines

Rotary Jet High-Impact Tank Cleaning Devices

HydroWhirl® Orbitor (HWO) Tank Cleaning Machines

Rotary Jet High-Impact Tank Cleaning Devices for Large Tanks

HydroWhirl Poseidon® (HWP) Tank Cleaning Nozzles

PTFE Corrosion-Resistant Slow Rotating Tank Cleaning Devices

HydroWhirl® Mini (HWM) 316L SS Tank Cleaning Nozzles

Reactionary Force Tank Cleaning Devices for Small Tanks

HydroWhirl® Mini (HWM) PVDF Tank Cleaning Nozzles

Reactionary Force Tank Cleaning Devices for Small Tanks

AFF Flat Fan Fire Protection Nozzles

FM Approved Nozzles for Water Mist and Offshore Fire Suppression

HydroWhirl® Orbitor 100 XC (HWO100 XC) Tank Cleaning Machines

Extreme Clean (XC)-High Impact With Slowest Rotation For Heavy Residue

BJH Flat Fan Nozzles With Tungsten Carbide Inserts

Interchangeable Fan Spray Nozzle Tips With Integral Strainer

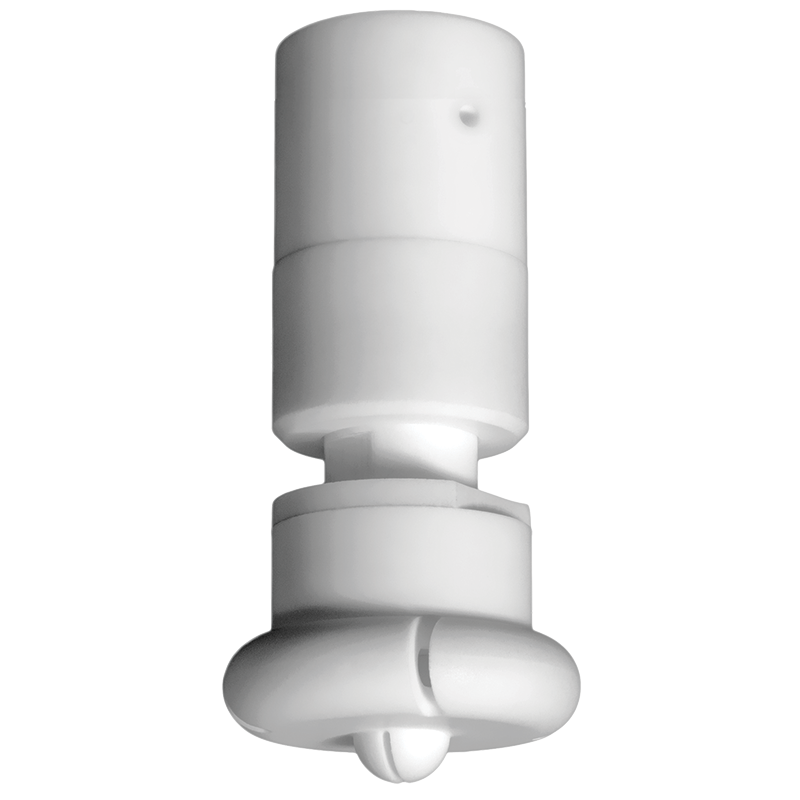

MicroWhirl® (MW) Misting & Fogging Nozzles

Patented Hydraulic Atomizing Nozzles with Drip-Free Operation

SAM Automatic Variable Air Atomizing Nozzles

External Mix Flat Fan or Full Cone Pneumatic Spray Nozzles

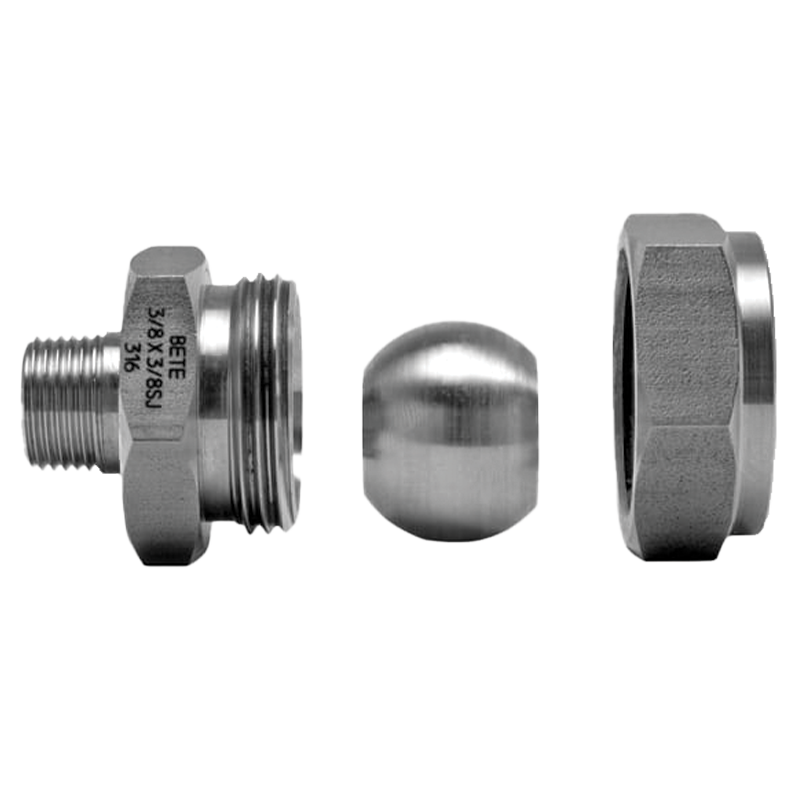

Twist & Dry® (TDL) Low Flow Spray Drying Nozzles

Low Flow and Compact Carrier Body Spray Dry Nozzles

SA SpiralAir® (SA) High-Flow Air Atomizing Spray Nozzles

Reduce Air Consumption With Efficient Two-Phase Atomization

XAXW Extra-Wide Hollow Cone Air Atomizing Spray Nozzles

Internal Mix, Pressure-Fed Pneumatic Nozzles

TH Right Angle Hollow Cone Nozzles

Tangential Clog-Resistant Nozzles for Flue Gas Desulfurization (FGD)

THW Wide Right Angle Hollow Cone Nozzles

Clog-Resistant Tangential Nozzles Available in Silicon Carbide

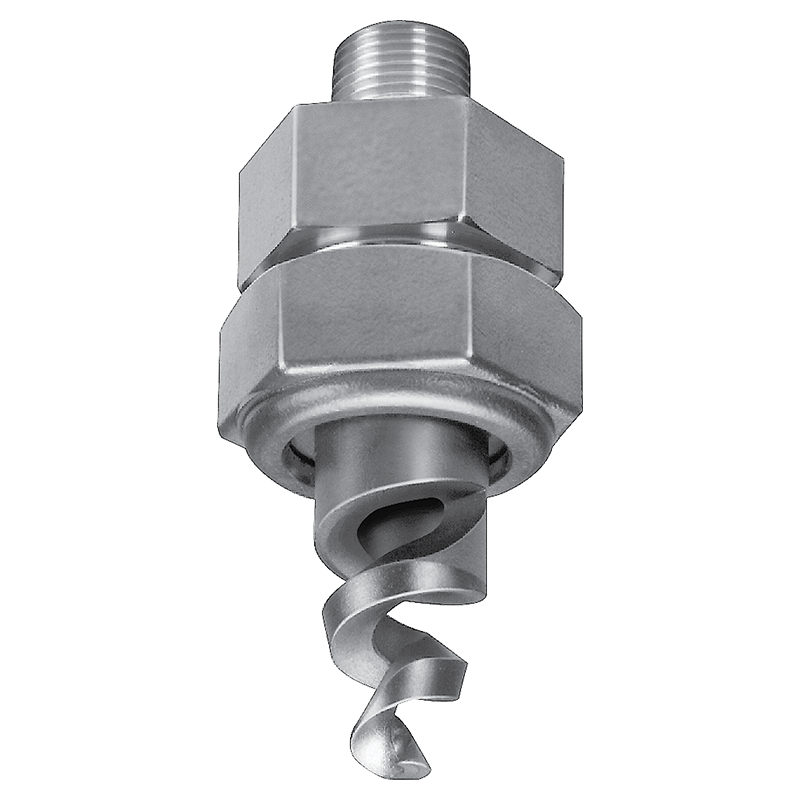

ST Abrasion Resistant Spiral Nozzles

Clog-Resistant Pigtail Nozzles Designed to Endure Limestone Slurry

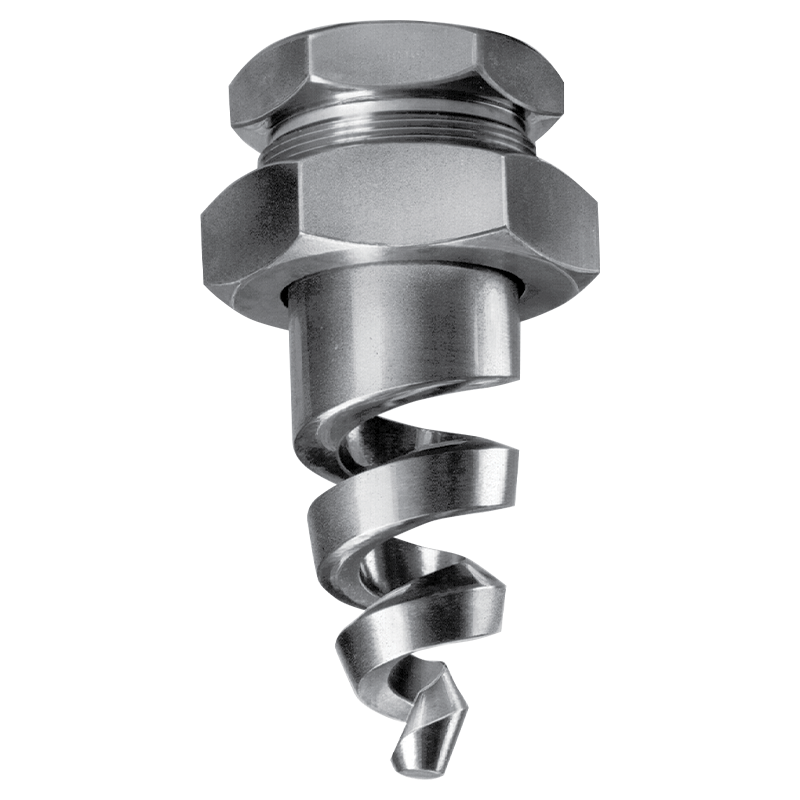

STXP Largest Free Passage Full Cone Spiral Nozzles

Abrasion and Clog-Resistant Pigtail Spray Nozzles

L Low Flow Misting & Fogging Nozzles

Very Fine Spray Hydraulic Atomizating Nozzles for Evaporative Cooling

NCJ Narrow Angle Hollow Cone Injector Nozzles

High Velocity Axial Spray Nozzles With Coarse Droplets

NFH Flat Fan Nozzles With Tungsten Carbide Inserts

High Impact Spray Nozzles for Maximum Life and Wear Resistance

NFV High-Impact Flat Fan Nozzles With Optional Integral Strainer

Removable Strainer Designed for Easy Cleaning

EZNF Quick Connect Straight Jet or Flat Fan Nozzles

Interchangeable Nozzle Tips With Base and Gasket

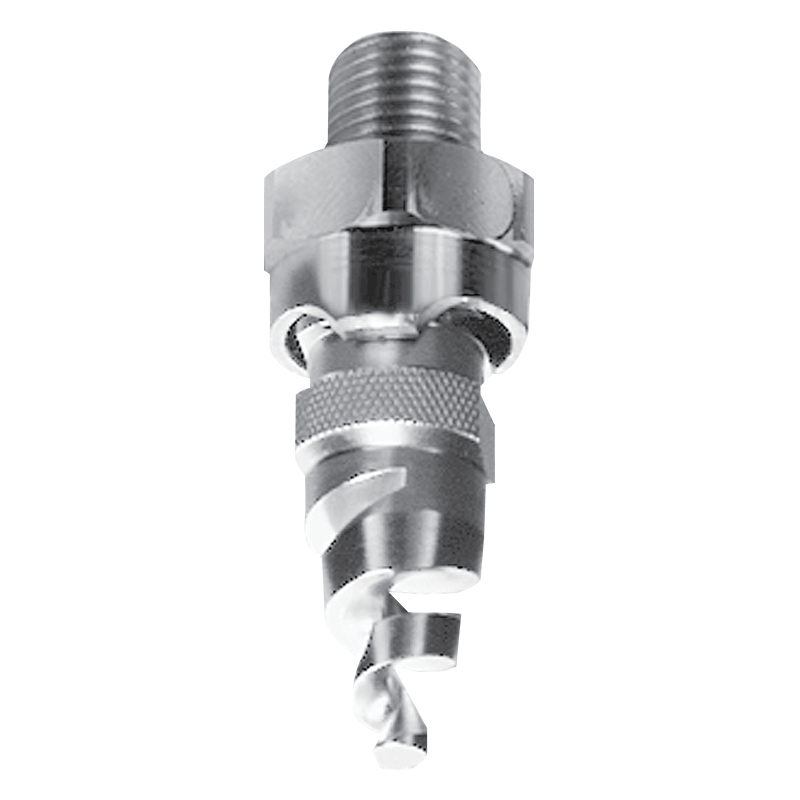

EZTF Quick Connect Full Cone or Hollow Cone Spiral Nozzles

Interchangeable Nozzle Tips With Base and Gasket

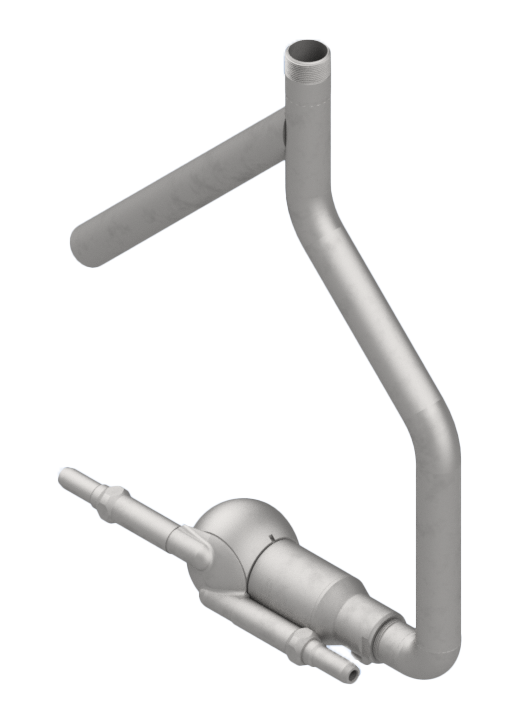

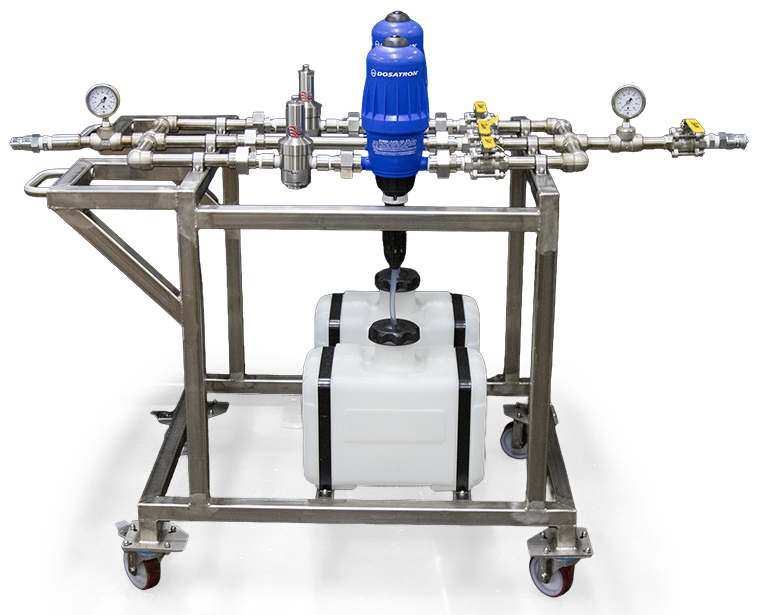

FlexiSan™ Modular Spray System

Open Plant Cleaning System: Simplify Sanitation, Save Time, and Cut Costs

Twist & Dry® (TD-HT) High-Temperature Spray Dry Nozzles

Spray Drying Technology for Higher Temperatures