DESIGN FEATURES

External mix: allows spraying of viscous materials

Able to spray high viscosity (100+ cP) fluids which require a round spray pattern

Liquid flow rate is controlled only by the liquid pressure. Liquid flow rate is not dependent on the air pressure making the nozzle performance easier to control.

Variable atomization

Precise metering of the liquid flow rate

HOW SPRAY PATTERN IS ACHIEVED

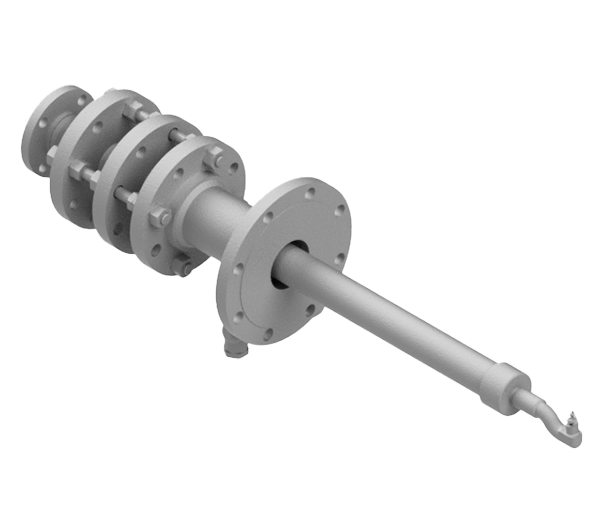

In a pressure-fed system, the liquid is supplied under pressure to either internal or external mix BETE XA Series nozzles. Air and liquid regulators control the fluid delivery pressure, while the air filter and liquid strainer ensure that the supplied fluids are high quality. Operational control is maintained by manual or solenoid valves used in conjunction with the various hardware assemblies

The air and liquid streams exit the nozzle independently through each orifice, creating a narrow-angle full cone spray pattern

Air and liquid flow rates can be controlled independently, allowing precise liquid metering

- Pipe: 1/8, 1/4

- Connection Methods: Thread (NPT, BSP, Female)