DESIGN FEATURES

Hygienic design

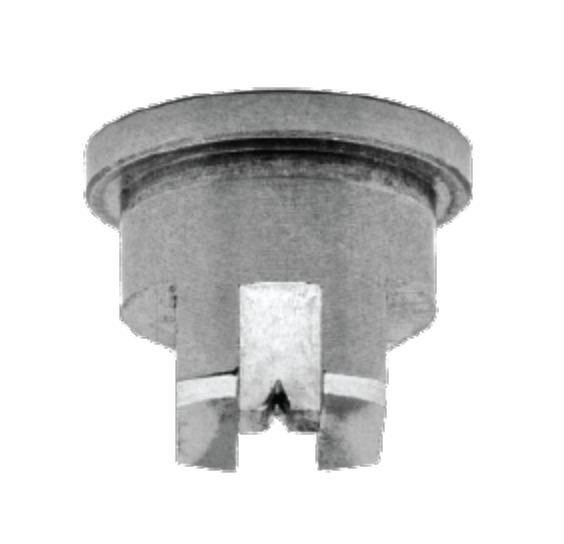

Interchangeable spray tips

Capable of cycling on/off up to 150 cycles per second

Does not require a compressed air source

EHP features straight through porting for in-series set-up

Paired with the FlexFlow spray controller, high-frequency cycling known as Pulse Width Modulation (PWM) can vary the liquid spray flow rate at constant supply pressure with little change in spray performance by adjusting the duty cycle

Product Benefits for Food Processing

Control a wide range of flow rates

Uniform and repeatable coverage improves product consistency

Reduce consumption of expensive coatings

Reduce overspray waste and improve product quality

Exact target coatings secure a clean and safe environment

Promote increased production

Reduce maintenance and downtime

Reliable spray dosing provides an accurate calorie count

Product Specifications

Interchangeable Nozzle Tip Options

For More Information Download Data Sheets

Notes: Due to pressure loss through the Electric HydroPulse body, the nozzle tip flow rate differs from the standard for each tip.

For the CW tips, full cone/hollow cone patterns are suitable for continuous operation only (not recommended for use with PWM control). Please reference the HydroPulse Electric Datasheet for a resolved flow rate range.

Related Products