DESIGN FEATURES

Unique patented clog-resistant design with no moving parts - upgrade your static spray balls

Allows passage of particle ¼" diameter, which is three times free passage of comparable spray balls

Made from FDA-compliant 316L SS for use in food-grade and sanitary Clean-In-Place (CIP) applications

Designed for industrial or hygienic small to medium sized tanks

Low pressure/high flow operation quickly cleans tank walls to reduce overall water consumption compared to a static spray ball

Fits through compact openings: either 2-1/2" (63.5 mm) or 3" (76 mm) diameter

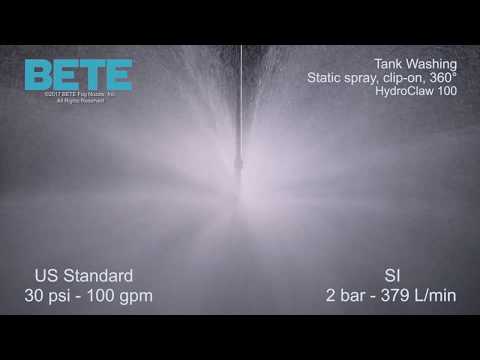

Clip-on nozzles include a low-profile retaining pin for secure connection

Self-draining, self-flushing

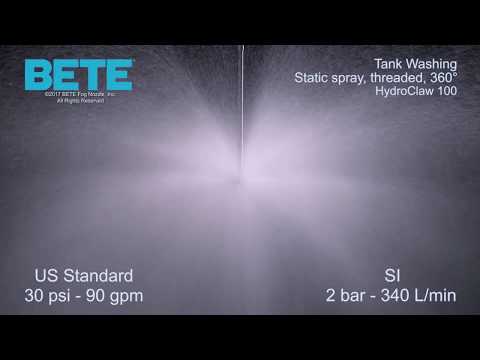

HOW SPRAY PATTERN IS ACHIEVED

A limited number of large diameter orifices create heavy straight jets that disperse using specially designed deflection cups. These deflection cups are designed with a slot to help break the jets into a uniform 360° omnidirectional spray pattern.

- Tube: DN20, 1in, 1 1/2in, DN40

- Pipe: 3/4, 1

- Connection Methods: Clip-on, Weld, Thread (NPT, G, Female)