DESIGN FEATURES

The HydroWhirl® Orbitor is a versatile tank cleaning machine designed for high-performance cleaning efficiency with extended operating life and reduced life cycle costs

High impact jet pattern provides complete spray coverage for large industrial and sanitary tanks, and tanker truck washing

High impact solid jet streams easily remove difficult soils

Easily repair on-site

Self-cleaning and self-lubricated

Ideal for use in larger tanks and where the product is difficult to clean

Designed with minimum moving parts to ensure extended operating life and reduced downtime

Two or four nozzle configurations

Available with ATEX approval

HOW SPRAY PATTERN IS ACHIEVED

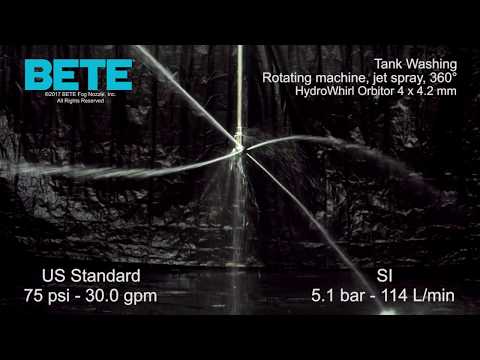

Rotary jets use the spray media flowing through internal gears on the body to rotate sets of high-impact jet nozzles through an efficient 2-axis orbital pattern, providing complete 360° coverage.

The jet pattern nozzles utilized on these assemblies provide significantly more impact and impingement force than other styles of tank cleaning nozzles, making them ideal for hard-to-clean residues and larger vessels.

- Pipe: 1, 1 1/2

- Connection Methods: Thread (NPT, BSP, Female)

Resources

HydroWhirl Orbitor Manual (English)

Download PDF

HydroWhirl Orbitor Manual (Spanish)

Download PDF

Tank Cleaning Brochure

Download PDF

Tank Cleaning Brochure Metric

Download PDF

HydroWhirl Orbitor Tank Cleaning for Fire Services Water Storage Case Study

Download PDF

HydroWhirl Orbitor Tank Cleaning for Food Processing Case Study

Download PDF