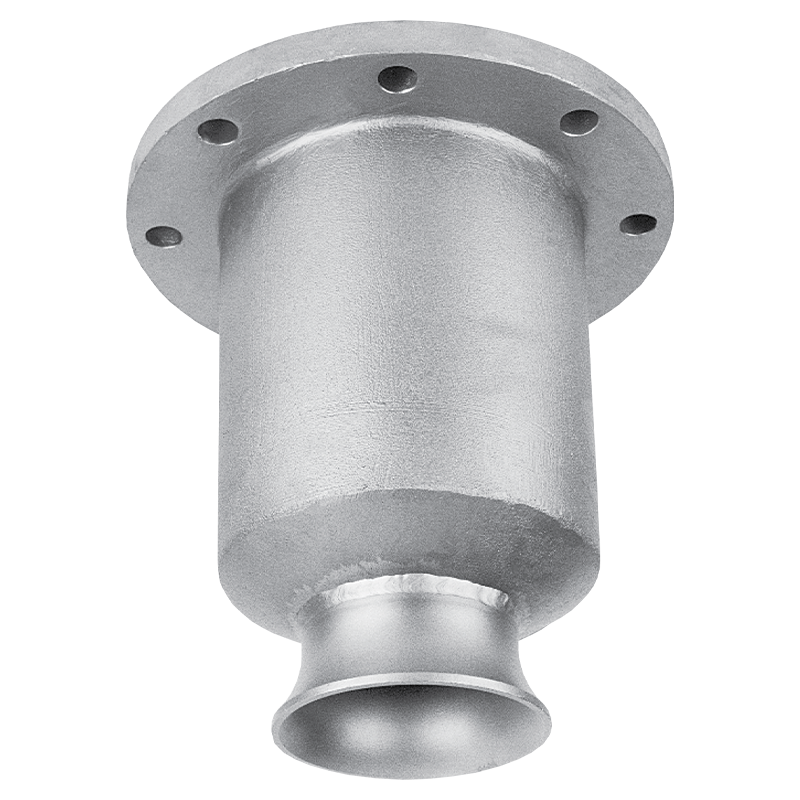

DESIGN FEATURES

Cast in a variety of alloys

Internal removable vane

Flanged connections available

HOW SPRAY PATTERN IS ACHIEVED

Atomization is achieved by the water being spun inside the nozzle and then exiting an orifice

Produces medium to coarse droplet size

More uniform pattern than spiral nozzles

Available Spray Angles

60 - 120°

Flow Rate Range

1.68 to 2970 gpm

Available Connection Types

- Pipe: 3/4, 1, 1 1/4, 1 1/2, 2, 2 1/2, 3, 4, 6

- Connection Methods: Thread (NPT, BSP, Male, Female)

Materials

Brass, Carbon Steel, 316

Flow Rates, Spray Angles, Connections

Full Cone

Select a nozzle number below for performance graph, drawings, and to request a quote.

Flow rate (gpm/lpm) is calculated at differential pressure (psi/bar).

Nozzle Number

Connection Sizes

Spray Angles

Flow Rate (gpm) @ Differential Pressure (psi) (Density: 1 SG)

3 psi

5 psi

10 psi

20 psi

50 psi

80 psi

1.68

2.13

2.95

4.09

6.29

7.84

2.01

2.56

3.54

4.91

7.55

9.41

2.68

3.41

4.72

6.54

10.1

12.5

2.82

3.58

4.96

6.87

10.6

13.2

4.02

5.11

7.08

9.81

15.1

18.8

4.71

5.99

8.29

11.5

17.7

22.0

5.38

6.84

9.47

13.1

20.2

25.2

6.05

7.69

10.7

14.8

22.7

28.3

6.72

8.54

11.8

16.4

25.2

31.4

7.39

9.40

13.0

18.0

27.7

34.6

8.06

10.2

14.2

19.7

30.2

37.7

9.40

12.0

16.6

22.9

35.3

44.0

10.7

13.7

18.9

26.2

40.3

50.3

11.4

14.5

20.1

27.8

42.8

53.4

13.4

17.1

23.6

32.7

50.4

62.8

16.1

20.5

28.4

39.3

60.5

75.4

16.8

21.3

29.5

40.9

62.9

78.4

19.4

24.7

34.2

47.4

72.9

91.0

20.1

25.6

35.4

49.1

75.5

94.1

23.5

29.8

41.3

57.2

88.0

110

26.8

34.1

47.2

65.4

101

125

28.2

35.8

49.6

68.7

106

132

31.5

40.1

55.5

76.8

118

147

33.5

42.6

59.0

81.8

126

157

38.9

49.4

68.5

94.8

146

182

40.2

51.1

70.8

98.1

151

188

47.1

59.9

82.9

115

177

220

53.8

68.4

94.7

131

202

252

60.5

76.9

107

148

227

283

63.9

81.2

112

156

240

299

67.2

85.4

118

164

252

314

78.6

99.9

138

192

295

368

80.6

102

142

197

302

377

84.0

107

148

205

315

393

87.3

111

154

213

328

409

90.7

115

160

221

340

424

107

137

189

262

403

503

121

154

213

295

453

565

126

160

222

308

473

591

134

171

236

327

504

628

141

179

248

344

529

660

168

213

295

409

629

784

235

298

413

572

880

1100

322

409

567

785

1210

1510

412

524

726

1010

1550

1930