MANUFACTURING CAPABILITIES

BETE Can Perform Every Procedure In-House, From Casting & Machining to Assembly

CIM – Advanced Computer Integrated Manufacturing

BETE's advanced CIM (Computer Integrated Manufacturing) environment links CAD workstations, a CAM part programming system, and CNC machining to optimize manufacturing lead times.

Reduced manufacturing times can improve your delivery

Our computerized scheduling system sequences every step in the production process, constantly adjusting the loads at each workstation to maximize throughput. This advantage makes it possible to manufacture any one of thousands of products within a short time while providing a reliable delivery forecast.

Manufacturing Process

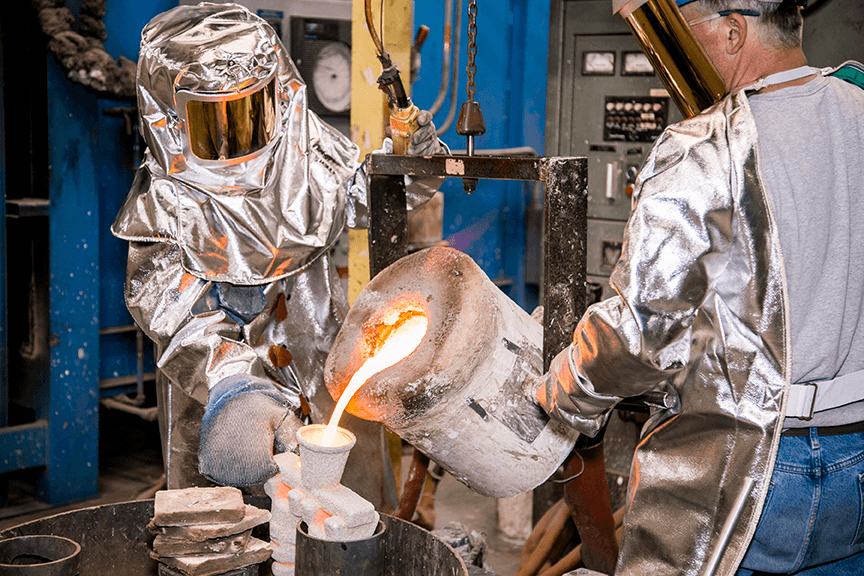

BETE is the only nozzle manufacturer with a complete in-house investment casting foundry.

In 1977, BETE made a significant new production commitment by setting up an in-house casting foundry, expanding our standard and exotic alloys inventory range. Ours is one of the first foundries in the world to cast Nickel Alloy C-22.

Investment Casting

Assembly & Fabrication

- ASME Certified Welding

- Grinding

- Plasma Spray Coating

- Ceramic Fabrication

- Plating

- Filament Winding of FRP

- Heat Treating

Injection Molding

CNC Machining