SPRAY NOZZLES & SPRAY SYSTEMS

Optimize your spray process and save resources with BETE spray technology. BETE is a pioneer in all areas of spray nozzle engineering, manufacturing, and applications. Since 1950 BETE has put nozzles into deep sea, deep space, and everywhere in between.

CONTACT AN EXPERT

Spray Nozzles, Spray Lances, & Spraying Systems

All Spray Nozzles

Discover BETE spray nozzles

Full Cone Spray Nozzles

Explore our full cone spray nozzles

Air Atomizing Nozzles

High-performance air atomizing nozzles

Tank Cleaning Nozzles

Find your tank cleaning solution

Spray Lances, Injectors, & Quills

Tailored to your specific process

Automated Spray Systems

Optimize your spray process

Learn How Our Customers Save Time & Money With BETE Spray Solutions

FlexFlow™ System Reduces Material Waste with Precision Coating for Frozen Pastry Manufacturer

Filo dough moving along an assembly line is filled with various ingredients, hand-rolled, and packaged. Before

rolling the dough, palm oil is hand-brushed by two linemen to act as the “glue” that holds the pastry together. The

manual application creates inconsistencies in the product, variation in nutritional content, excessive use of oil,

and uneven coverage – adding to the overall cost of production.

Read More

SpiralAir® Nozzle Significantly Reduces Air Consumption Usage in Flue Gas Cooling

Cooling of exhaust gases from the Electric Arc Furnace (EAF) is critical to controlling temperatures of

the gas in the ductwork as it enters the baghouse to prevent a fire. Air atomizing nozzles are ideal for

cooling the gases because they produce very fine droplets, but air consumption can be high and costly

if the proper nozzle is not selected.

Read More

Avoiding Costly Damage and Repair of Refinery Equipment With Spray Injectors

Quills are not always the best method for injecting chemical inhibitors where spray distribution is

critical. For these applications, fabricated spray injectors with a nozzle produce more accurate results for spray injection.

Read More

Featured Products

Blog Posts

What Factors to Consider When Selecting a Nozzle Material

Today, we’ll examine the crucial factors influencing the selection of nozzle materials. Spray nozzles play a pivotal role in various applications, and selecting the appropriate material can significantly impact performance and longevity. Understanding Spray Nozzle...

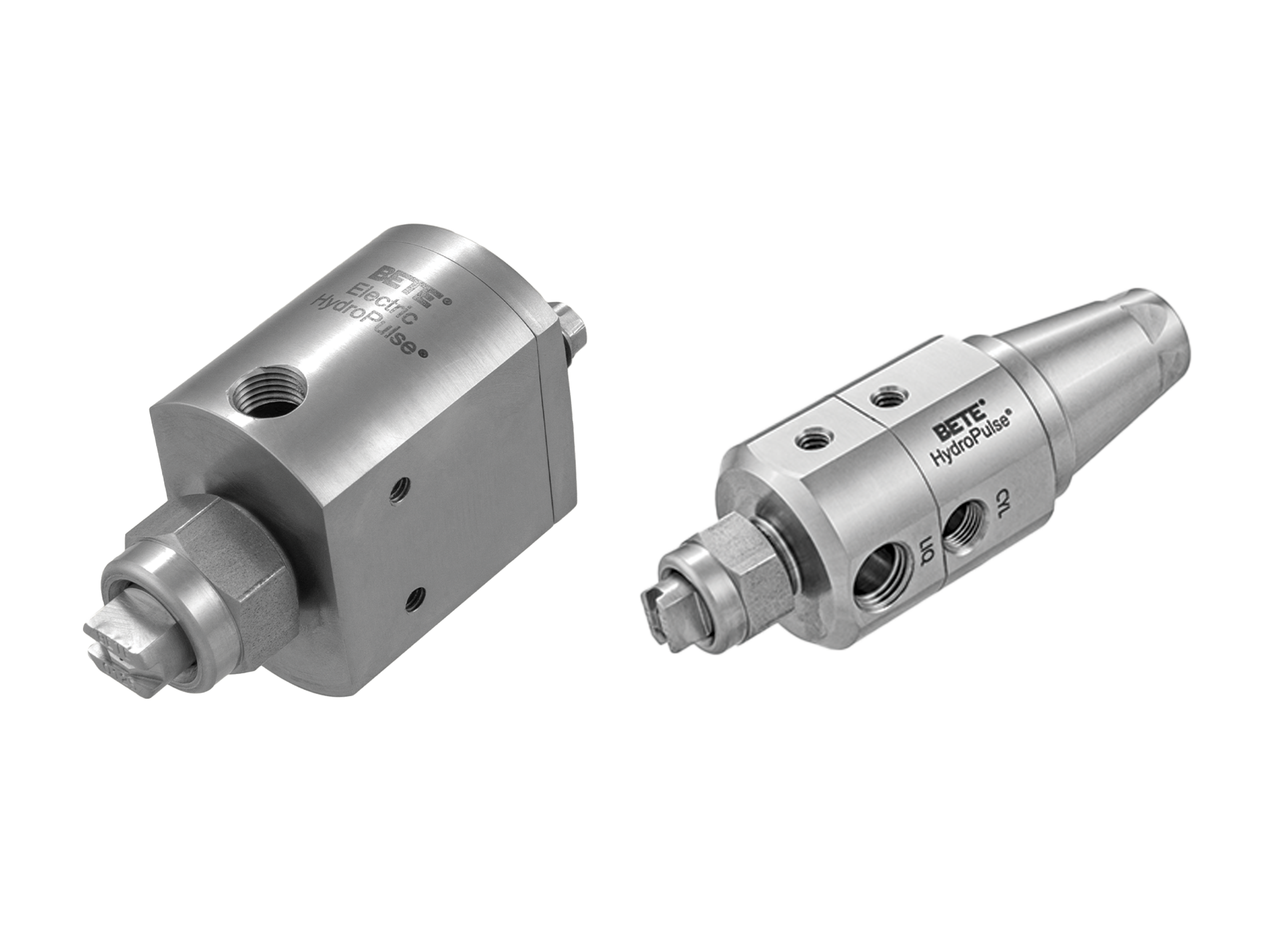

Choosing the Right Actuation: Electrical vs. Pneumatic Automatic Spray Nozzles

Automatic spray nozzles offer several advantages, including precise uniform spray coverage, improved product consistency, minimized overspray, and reduced waste. They are essential for many tasks like cleaning, coating, or cooling, where precise intermittent spraying is...

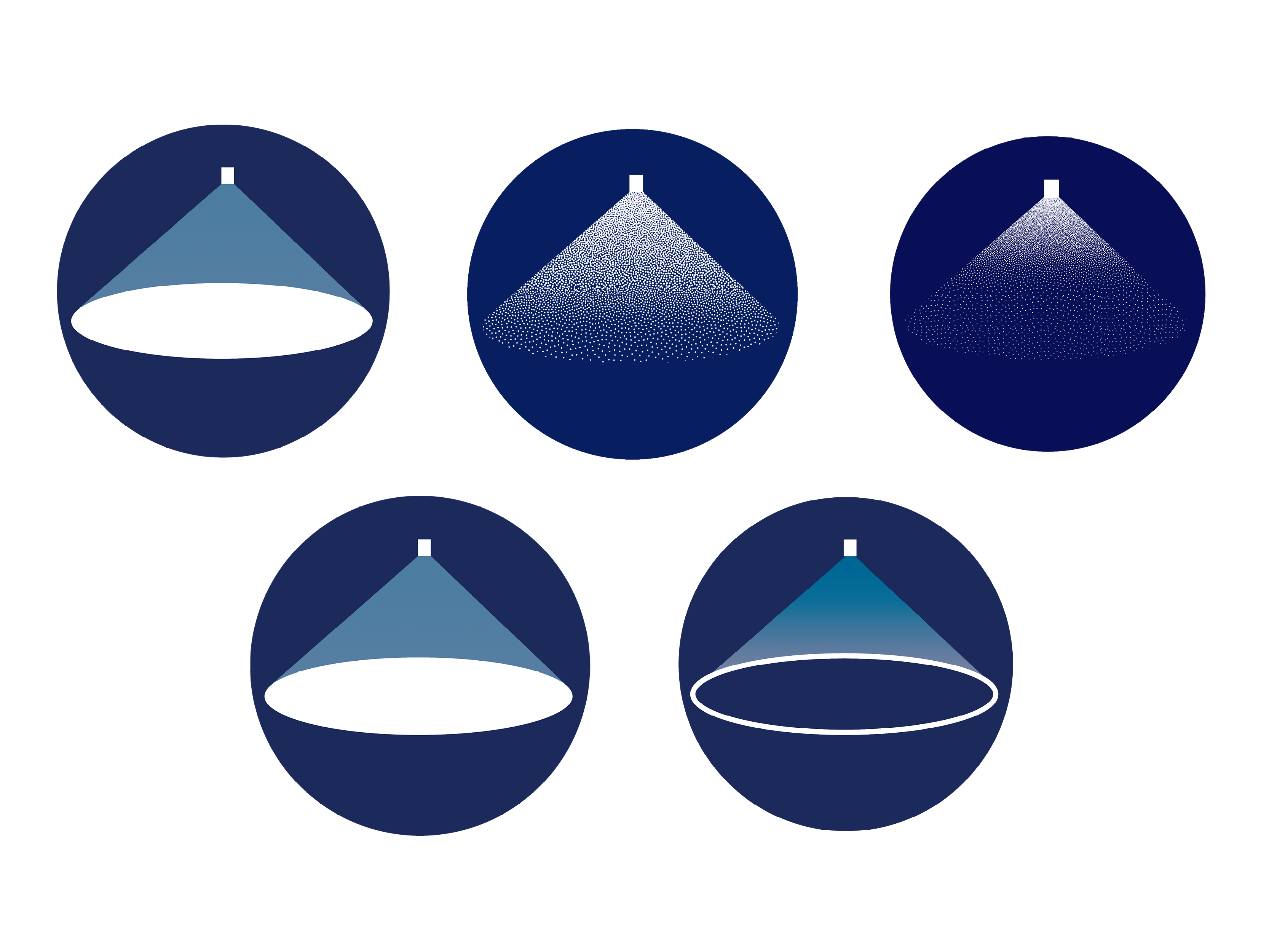

Exploring the Top Five Spray Pattern Types

Nozzles are essential components that produce different spray patterns based on their design. Understanding these patterns can help you choose the right nozzle for your spray application. In this article, we’ll explore five common types...

Discover the BETE Difference

Our spray technology innovations improve sustainable operations in a broad range of industries – including Food & Beverage Processing, Chemical Processing, Energy, and Pollution Control. We listen to and partner with our customers to ensure the optimal solution for their spraying challenge.

LEARN MORE ABOUT BETE