ABOUT BETE

Our Mission

Our Vision

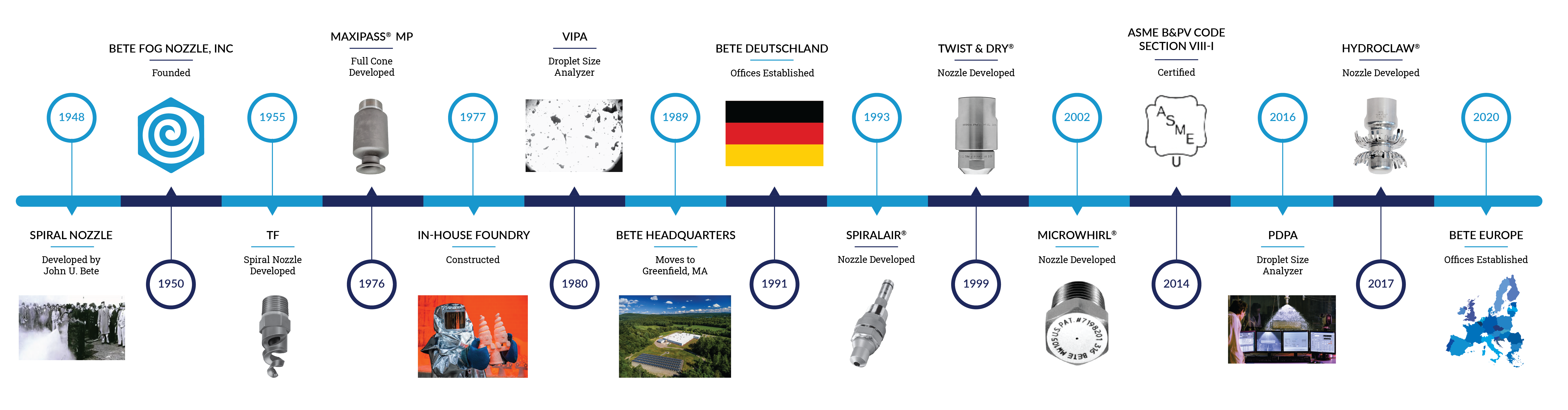

Our History

Founded in 1950 in Greenfield, MA, BETE operated as a family-owned business until 2024, when Matthew Bete's strategic partnership with EXAIR opened the door to significant opportunities and growth. BETE's established USA manufacturing and strong international presence continue to thrive with the support of our distributor network and growing subsidiaries in Germany and Europe.

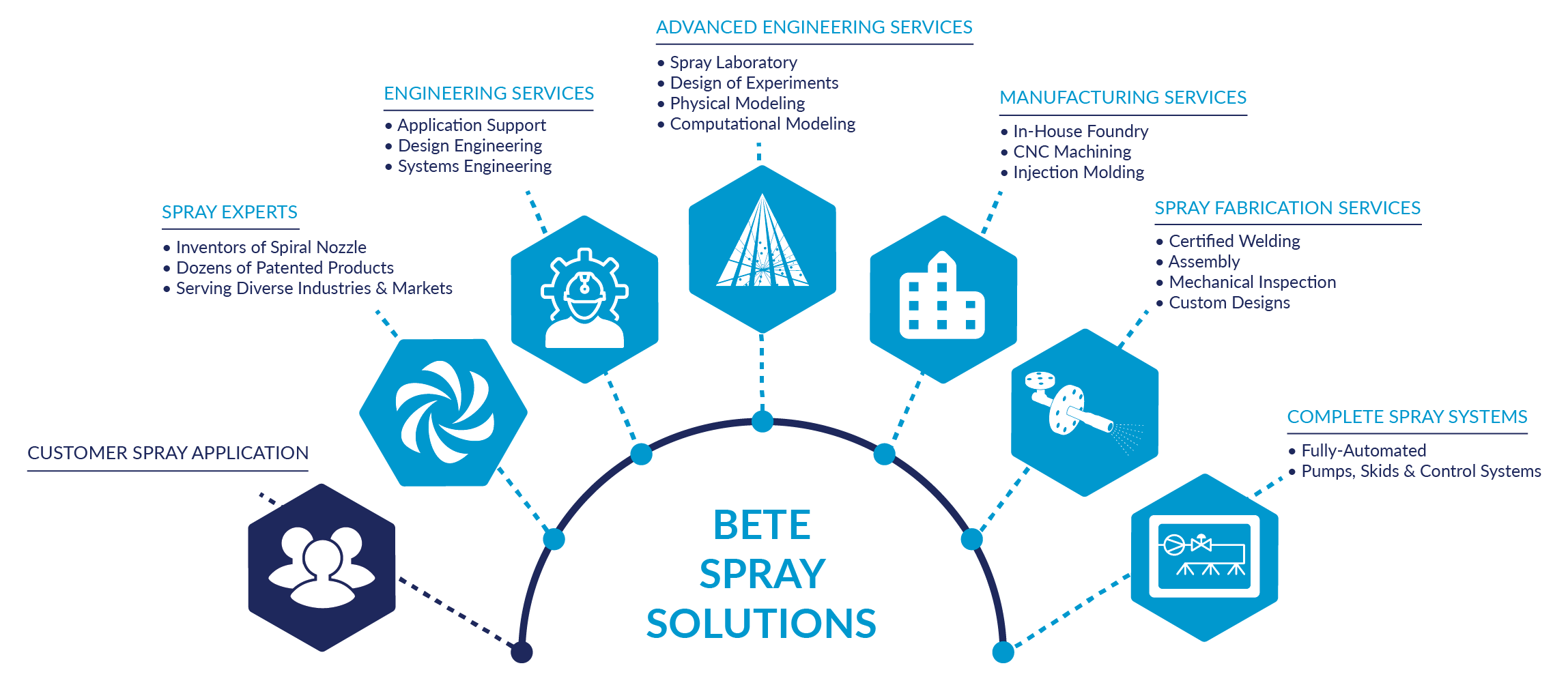

BETE’s spray technology is used worldwide to optimize processes in various markets, including food, beverage, petrochemical, chemical, and pollution control. We manufacture tens of thousands of different products, including fog and misting nozzles, tank cleaning nozzles, material injection nozzles, custom spray lances, fabrications, and spray systems.

We offer Advanced Spray Engineering Services to solve more challenging and critical problems, including the ability to perform CFD studies and physical testing. Our decades of experience in spray design and applications engineering, combined with our CNC machine shop, foundry, and spray lab, are used to design, manufacture, and test our products.

Our innovations improve sustainable operations in a broad range of industries. We listen to and partner with our customers to ensure the optimal solution for their spraying challenge.

Our Values

People: Our most valuable asset and source of present and future strength is our people. They provide ideas and vitality, determine our reputation and establish a corporate personality visible to all. We will, at all times, treat each other with mutual respect as we carry out our responsibilities.

Products: Whether our products are hardware or services, they should be the best available Quality in serving our customer needs throughout the world. They are ultimately how our customer perceives us and must be the best.

Personality: Our corporate personality projects the essence of our company both internally and to our customers. This is a positive, can-do attitude, yielding problem-solving resolutions to our customers and coworkers.

Profit: Profit is a measure of our success in efficient performance and is absolutely essential to survival and growth.

The BETE Advantage

BETE Terms & Conditions

BETE Fog Nozzle Inc. (hereinafter “BETE”) warrants the items sold under this invoice against defects in materials, or workmanship, for a period of 18 months from the date of shipment. During this period BETE will repair or replace defective parts, or accept them in exchange for a refund, at the buyer’s discretion, without charge.

Factors outside of BETE’s control, including but not limited to corrosion, erosion, chemical incompatibility, incorrect installation or use, physical damage, or modifications performed by anyone other than BETE, will void this warranty.

In all cases, BETE’s liability shall be limited to the value of the product as invoiced. There is no implied warranty of merchantability or fitness for a particular purpose other than this expressed warranty. In no event shall BETE be liable for incidental, consequential, special, or exemplary (punitive) damages, or loss of profit. In the event of a claim against this warranty, BETE reserves the right for itself or its agent to inspect both the product and the site of use before honoring the warranty. All items returned, refunded, or replaced under this warranty become the property of BETE.