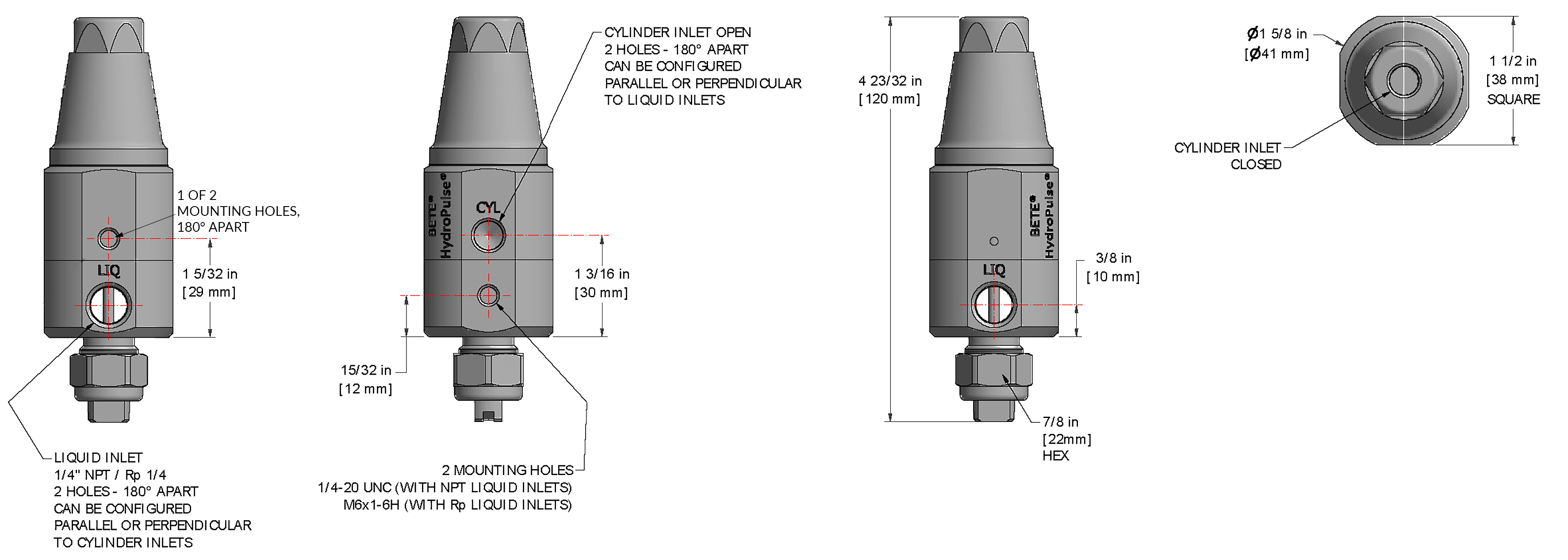

DESIGN FEATURES

The precise intermittent spray uses liquid pressure as the force for atomization

Improves product quality with uniform, repeatable coverage and drip-free performance

Interchangeable flat fan, full cone, or hollow cone nozzle tips provide a wide range of spray patterns and volumes to match requirements

Pneumatically actuated for precise on/off spray directly on the target

Minimal overspray reduces waste and maintains a clean, safe environment

Straight through porting for fluid recirculation

Hygienic connections and mounting brackets are available options

Product Specifications

Liquid inlet connection

¼” NPT or BSPP, liquid; ⅛” NPT

or BSPP, cylinder air; or DN10 tri-clamp

Maximum liquid flow rate

12.6 GPM / 57.7 LPM

Maximum rated pressure

600 PSI / 42 bar

Thermal insulation class

-15° F to 400° F / -26° C to 204° C

Air cylinder pressure

30 PSI to 250 PSI / 2 bar to 17 bar

Air cylinder operation

Single acting (spring return)

or double acting

Maximum cycle frequency

3 cycles / sec

Nozzle construction

Stainless steel wetted components, Viton® (FKM) seals

Interchangeable Nozzle Tip Options

For More Information Download Data Sheets

HydroPulse Catalog Datasheet

HydroPulse - Metric Catalog Datasheet